(Image by permission from "The Plaza del Herrero"

in Ecuador.)

"Golden

Age Forge"

Welcome

Friends!

"Foundry" spoken here too.

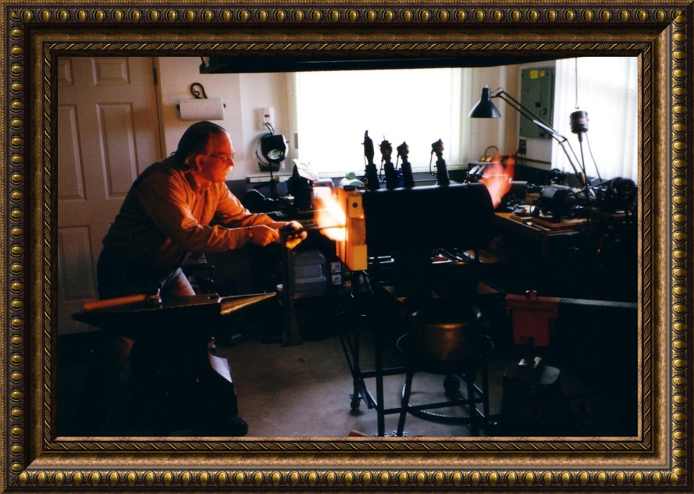

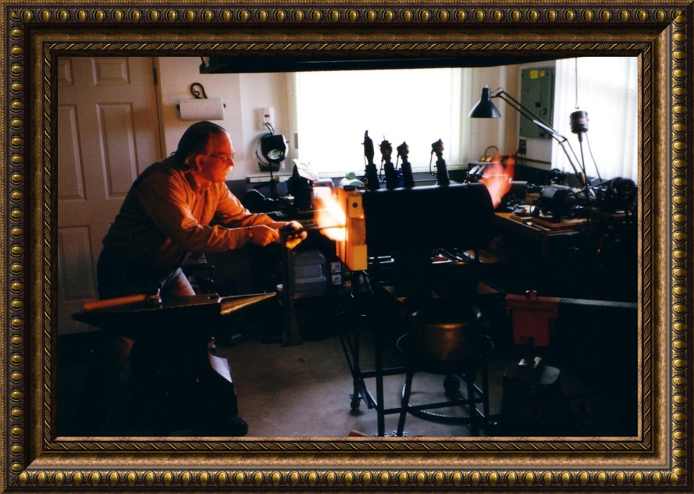

I am about to forge-weld a Spontoon pipe-axe head. Click on image for full size.

(This excellent picture was taken by my

apprentice, Kevin Brown.)

An

Addition to My Shop - Out of this world!

This is a 64 pound nickle-iron meteorite from Argentina that

fell about 4000 years ago!

Warning!

I provide the following

information as a service to the blacksmithing community. Although the

designs I employ in building my burners and forges are safe and

reliable in the way that I use them, the same may not be the case for

you. You assume all risk in using this information, or any

other information on this page. Other designs that I may have

posted here, or on my other pages, have been submitted by

other smiths, and I have no experience with most of them. Use care and

good sense in using any of these designs. Get help from a knowledgeable

smith if you are new to this work. Don't take chances because these

tools can cause injury, blindness, or even death, if used improperly.

Also, be sure you are in a well ventilated space (see the Nighthawk CO

& explosive gas detector paragraph), or better yet,

work outside. Additionally, never operate a forge that is

connected directly to a propane tank that is near a forge, or indoors.

An emergency pressure valve release could instantly place you in the

middle of a fireball. Follow all local codes regarding

indoor use of propane, and I believe indoor use of a propane

tank violates code everywhere in North America, and most of Europe. A

new concern has arisen with the introduction of the "Mongo Burner

Series." Please read carefully all the information in the separate "Safety Warnings and

Considerations" information which heads the "Mongo Burner

Series" section. Thank you.

I provide the following

information as a service to the blacksmithing community. Although the

designs I employ in building my burners and forges are safe and

reliable in the way that I use them, the same may not be the case for

you. You assume all risk in using this information, or any

other information on this page. Other designs that I may have

posted here, or on my other pages, have been submitted by

other smiths, and I have no experience with most of them. Use care and

good sense in using any of these designs. Get help from a knowledgeable

smith if you are new to this work. Don't take chances because these

tools can cause injury, blindness, or even death, if used improperly.

Also, be sure you are in a well ventilated space (see the Nighthawk CO

& explosive gas detector paragraph), or better yet,

work outside. Additionally, never operate a forge that is

connected directly to a propane tank that is near a forge, or indoors.

An emergency pressure valve release could instantly place you in the

middle of a fireball. Follow all local codes regarding

indoor use of propane, and I believe indoor use of a propane

tank violates code everywhere in North America, and most of Europe. A

new concern has arisen with the introduction of the "Mongo Burner

Series." Please read carefully all the information in the separate "Safety Warnings and

Considerations" information which heads the "Mongo Burner

Series" section. Thank you.

An additional item that should

be of interest to you is obtaining an explosive gas/CO

detector for your working space. Mark Manley, of "Manley

Metal Works," Silverton, Oregon, provided a short piece of very

important information in the Winter 2000 issue of "Hot Iron News" that

I feel needs to be passed on to a wider audience. There is a very

reasonably priced digital read-out combination explosive gas and CO

detector available in local hardware, building supply, and other

stores. I was concerned about having a CO monitor in my shop, even

though I have a very efficient induced draft hood in my shop. The

detector is made by "Kidde Safety," and is called

the "Nighthawk." I will not go into the specs for

the instrument here, it is available on the Internet if you look up

"Kidde Safety," but I will say that it is a very finely

designed and built instrument. It runs on 110 VAC, and has a 12 VDC

back-up. It plugs directly into an outlet, or the transformer plug

detaches for remote mounting up to 6' from the plug. You can easily

check your CO level with a quick glance at the digital read-out. If it

detects any kind of flammable gas it will instantly sound a very loud

audible alarm, and the word "Gas" will display on the digital display.

If it detects CO it will sound a different audible alarm and display

the PPM level of the gas. Also, you will know it's operating because

the blinking decimal point in the digital read-out indicates it's

operating and sampling the air in your shop.

An additional item that should

be of interest to you is obtaining an explosive gas/CO

detector for your working space. Mark Manley, of "Manley

Metal Works," Silverton, Oregon, provided a short piece of very

important information in the Winter 2000 issue of "Hot Iron News" that

I feel needs to be passed on to a wider audience. There is a very

reasonably priced digital read-out combination explosive gas and CO

detector available in local hardware, building supply, and other

stores. I was concerned about having a CO monitor in my shop, even

though I have a very efficient induced draft hood in my shop. The

detector is made by "Kidde Safety," and is called

the "Nighthawk." I will not go into the specs for

the instrument here, it is available on the Internet if you look up

"Kidde Safety," but I will say that it is a very finely

designed and built instrument. It runs on 110 VAC, and has a 12 VDC

back-up. It plugs directly into an outlet, or the transformer plug

detaches for remote mounting up to 6' from the plug. You can easily

check your CO level with a quick glance at the digital read-out. If it

detects any kind of flammable gas it will instantly sound a very loud

audible alarm, and the word "Gas" will display on the digital display.

If it detects CO it will sound a different audible alarm and display

the PPM level of the gas. Also, you will know it's operating because

the blinking decimal point in the digital read-out indicates it's

operating and sampling the air in your shop.

I bought one of

these instruments for my shop, and I was so impressed with it that I

went down and bought a second one for my home, which has natural gas

heat, gas hot water, and a natural gas fireplace insert. I priced CO

detectors on the McMaster-Carr web site, and CO detectors alone were

$170, where this combination instrument is only $59 at my local Home

Depot. Considering how deadly CO can be, this instrument is very

inexpensive, and well worth the investment. It may well save

your life. After Mark installed his "Nighthawk," he discovered that he

had been exposing himself to CO levels of 30-160 PPM while running his

forge! Thanks for the tip Mark.

I bought one of

these instruments for my shop, and I was so impressed with it that I

went down and bought a second one for my home, which has natural gas

heat, gas hot water, and a natural gas fireplace insert. I priced CO

detectors on the McMaster-Carr web site, and CO detectors alone were

$170, where this combination instrument is only $59 at my local Home

Depot. Considering how deadly CO can be, this instrument is very

inexpensive, and well worth the investment. It may well save

your life. After Mark installed his "Nighthawk," he discovered that he

had been exposing himself to CO levels of 30-160 PPM while running his

forge! Thanks for the tip Mark.

Note:

There has been a recall of Kidde Safety "Nighthawk" gas and

CO detectors. This does not affect any detectors sold after the date

that I posted the above information, however you may check your unit by

going to http://www.cpsc.gov/cpscpub/prerel/prhtml99/99082.html.

A Word About Obtaining My Help

I am no longer

able to offer my support to help solve problems you may have with your

burners or forge. I have reached the point that something has to give.

Two to three hours a night answering questions has brought my metal

working each evening of the week to a stand still. I will continue to

update my blacksmithing pages, and may now also have the time to clean

out some of the outdated and conflicting information in my pages,

however, I will no longer be able to troubleshoot your system. If you

build your burner to the design specs and information shown and

discussed on my pages, including in the Troubleshooting Document and

FAQ, your burner should work well. If it doesn't, then its not built

correctly, and you will need to make some adjustments after looking

through the available information. The best thing to look at when fine

tuning your burner are the various flame images I have

posted. If yours looks like these images, you probably have it right.

Here are a few helpful links.

I am no longer

able to offer my support to help solve problems you may have with your

burners or forge. I have reached the point that something has to give.

Two to three hours a night answering questions has brought my metal

working each evening of the week to a stand still. I will continue to

update my blacksmithing pages, and may now also have the time to clean

out some of the outdated and conflicting information in my pages,

however, I will no longer be able to troubleshoot your system. If you

build your burner to the design specs and information shown and

discussed on my pages, including in the Troubleshooting Document and

FAQ, your burner should work well. If it doesn't, then its not built

correctly, and you will need to make some adjustments after looking

through the available information. The best thing to look at when fine

tuning your burner are the various flame images I have

posted. If yours looks like these images, you probably have it right.

Here are a few helpful links.

FAQ

Forge & Burner

Troubleshooting Document

Some Often

Asked Questions

EZ-Burner

Construction

Rich To

Lean Flame Image

1) T-Rex Flame

Image - Ideal Neutral Flame

2) Side-arm

Burner Flame Using Temporary Cast Iron Test Nozzle - Slightly Reducing

Flame

3) Another

Flame Image - Oxidizing Flame

The bottom three

flame images give you views of burner flames adjusted to 1) neutral, 2)

slightly reducing, and 3) strongly oxidizing. The burners have nothing

to do with it, just the choke settings. All of these images could have

been done with the T-Rex, or Side-arm burners. At your high end gas

pressure, if you have achieved a flame similar to the oxidizing flame

shown in the bottom image, #3, you will then have full control over the

burner flame across the full pressure range. This will allow you to

achieve oxidizing, neutral, or reducing, flames as needed by simply

adjusting the choke. You will then have a properly functioning burner.

The bottom three

flame images give you views of burner flames adjusted to 1) neutral, 2)

slightly reducing, and 3) strongly oxidizing. The burners have nothing

to do with it, just the choke settings. All of these images could have

been done with the T-Rex, or Side-arm burners. At your high end gas

pressure, if you have achieved a flame similar to the oxidizing flame

shown in the bottom image, #3, you will then have full control over the

burner flame across the full pressure range. This will allow you to

achieve oxidizing, neutral, or reducing, flames as needed by simply

adjusting the choke. You will then have a properly functioning burner.

Links Local to My Site

The Full Site Map - Lists All Pages

on This Site

Golden Age Forge Gallery

All Three Volumes

of "Best of Theforge" Zipped - (257K)

-or-

The Best of Theforge -

Vol 1

The Best of

Theforge - Vol 2

The Best of

Theforge - Vol 3

Subject

Index for This Page

Safety Warning

Additional Forge and Burner

Design Information

My Shop is Born

My Open Air Smithy

My Blacksmithing Background

& Big Coal

Forge

Jet Pump Motor 12" Disk Grinder

My 4-Burner Forge

Idle/Full Valve Arrangement

The Reil Burner

The "T-Rex" Burner Series

Ribbon Burner

Ribbon Burner

The Restoration of My Little Giant

Easy Hammer

An Update

Some Useful Tools

-Iron Wheel

Carousel Tongs Rack

-Double Reversed

Twisting Jig

-Torch Cart

-Universal

Position Welding Jig

Table

Some Blacksmithing and Foundry

Links

New Arrival, A Swarm

Closing

Forge and Burner Design

Information

This

page has information

about several of my coal and gas forges, and the "Reil and EZ-Burners,"

but

most of the forge and burner design information can be found on my

other

page, the Forge and Burner Design

Page. Please

visit my other page if you are in need of further information. I should

add

that you should check out the "Mongo

Burner,"

and the smaller versions of this burner, as well as the

T-Rex and

Shorty

burners, before you settle

on a burner design to build for your own forge or melting furnace. This

information is on my other page, along with a huge volume of other

information

related to this topic. Do explore this present page first however,

because

it does have a lot of information of value that is not found

on my other

pages. Thank you.

This

page has information

about several of my coal and gas forges, and the "Reil and EZ-Burners,"

but

most of the forge and burner design information can be found on my

other

page, the Forge and Burner Design

Page. Please

visit my other page if you are in need of further information. I should

add

that you should check out the "Mongo

Burner,"

and the smaller versions of this burner, as well as the

T-Rex and

Shorty

burners, before you settle

on a burner design to build for your own forge or melting furnace. This

information is on my other page, along with a huge volume of other

information

related to this topic. Do explore this present page first however,

because

it does have a lot of information of value that is not found

on my other

pages. Thank you.

The

Construction of My New Smithy

Shop on 26 June 01

(Click thumbnail to go to my Shop Construction Page.)

I

decided that

this narrative was becoming too long to keep on this page. I have

created

a separate page dedicated to the construction of the shop where I can

include

more detailed information and more images. Please visit my

"Shop Construction Page" if

you are interested in

the special features my "smithy" has incorporated into it. Thank you.

I

decided that

this narrative was becoming too long to keep on this page. I have

created

a separate page dedicated to the construction of the shop where I can

include

more detailed information and more images. Please visit my

"Shop Construction Page" if

you are interested in

the special features my "smithy" has incorporated into it. Thank you.

My

Old Open Air

Smithy/Foundry

Working at my coal forge

(Click image for enlarged view)

In the background

of the above picture you can see a foundry pour Blaine and I have just

finished.

It is on the table cooling. It is an aluminum Dutch oven lid with a

special

name cast into it. It was a Christmas gift for one of Blaine's friends.

If

you will click here you

can see Blaine holding the

results of our efforts. I think it was worth the work. For a close-up

of

the casting click here.

What you see in

the image is what I used to have to call my "smithy." I am elated to

report

that I am now working out of a very fine shop building, shown above,

and

no longer have to be an armchair smith in the winters. :-)

In the background

of the above picture you can see a foundry pour Blaine and I have just

finished.

It is on the table cooling. It is an aluminum Dutch oven lid with a

special

name cast into it. It was a Christmas gift for one of Blaine's friends.

If

you will click here you

can see Blaine holding the

results of our efforts. I think it was worth the work. For a close-up

of

the casting click here.

What you see in

the image is what I used to have to call my "smithy." I am elated to

report

that I am now working out of a very fine shop building, shown above,

and

no longer have to be an armchair smith in the winters. :-)

My big gas forge,

daughter Natalie, and 12" disk

grinder

This

is my main work-horse

forge. The burner arrangement allows me to run three burners equally

spaced,

close together, or three burners equally spaced, and farther apart. I

never

run all four at one time, and normally only use one burner. The forge

has

an interior movable back wall, and an "idle/full valve arrangement

which

is hidden behind the grinder. The cart has two swing-up side tables,

and

a swing-up, adjustable, work support bracket

(Image1, Image2) in

front....a very useful addition to a basic forge. The cart allows easy

movement

of the forge by inserting two "wheelbarrow" type handles into the side

brackets

provided. Here is another image showing my entire

"smithy" setup as it is in

the summer, but all of

which will soon be in my new shop.

This

is my main work-horse

forge. The burner arrangement allows me to run three burners equally

spaced,

close together, or three burners equally spaced, and farther apart. I

never

run all four at one time, and normally only use one burner. The forge

has

an interior movable back wall, and an "idle/full valve arrangement

which

is hidden behind the grinder. The cart has two swing-up side tables,

and

a swing-up, adjustable, work support bracket

(Image1, Image2) in

front....a very useful addition to a basic forge. The cart allows easy

movement

of the forge by inserting two "wheelbarrow" type handles into the side

brackets

provided. Here is another image showing my entire

"smithy" setup as it is in

the summer, but all of

which will soon be in my new shop.

My

four burner propane forge

is going on its 5th year of use, and its interior is still in very good

condition. The floor is a little messed up near the front from welding

flux,

but I quickly learned to use a 1/2" thick "slick" made from a kiln

shelf

to protect it when doing forge welding. Barring accident, I would

expect

to get another 5 years or more out of the lining without any problems,

perhaps

considerably more. Since building this forge I have not even moved my

big

coal forge out for use even once, although I have fired up my small

open

pan coal forge on several occasions for items that would not fit in the

chamber

of my gas forge. The gas forge is a joy to use due to its almost

instant

heat and incredible economy of operation. Use of the coal forges will

probably

end completely when I have complete construction of the

Clam-shell forge.

My

four burner propane forge

is going on its 5th year of use, and its interior is still in very good

condition. The floor is a little messed up near the front from welding

flux,

but I quickly learned to use a 1/2" thick "slick" made from a kiln

shelf

to protect it when doing forge welding. Barring accident, I would

expect

to get another 5 years or more out of the lining without any problems,

perhaps

considerably more. Since building this forge I have not even moved my

big

coal forge out for use even once, although I have fired up my small

open

pan coal forge on several occasions for items that would not fit in the

chamber

of my gas forge. The gas forge is a joy to use due to its almost

instant

heat and incredible economy of operation. Use of the coal forges will

probably

end completely when I have complete construction of the

Clam-shell forge.

I

made my 12" disk grinder

from a new 3250 rpm,

1-1/2 hp, jet pump motor, and used a precision backing plate made by

"Shopsmith",

which was also new.

It has a 5/8" motor shaft hole, and the platen is about 1/8"

thick.

It is not keyed to the shaft, just has a large set screw, so you need

to

have a 5/8" motor shaft with a flat side, or file one on it. I actually

filed

a rounded notch in the shaft, instead of a flat, to engage the set

screw

in order to make it more secure from loosening and sliding on the

shaft.

The platen is very precision made, and of high strength steel. When I

turned

it on for the first time I was amazed to see it rotate with virtually

no

wobble at all...perfectly flat running. I forged the handle from

a 3/8"

x 2" steel bar which I split lengthwise, and then punched and

shaped

to allow it to be attached directly by using the motor mounting bolts.

I

think that this 3/8" thick forging would be very difficult to make if

you

do not have a swage block. It is not easy even with a swage block.

Notice

the back end of the handle, which has a down dropped and rounded

partial

flange to prevent it sliding out of the hand. The handle is rock solid

and

secure in use. (Note:

The "Shopsmith" disk grinder

platen comes with a warning label stating not to spin it faster than

2000

rpm. I do not recommend you do so, as I am doing, unless you do your

own

engineering design calculations to determine if the steel

platen can

be rotated safely at the higher speed. I make no suggestion that it is

safe

to do so. If you decide to spin it at a higher than recommended speed, you

do so entirely at your own

risk.)

I

made my 12" disk grinder

from a new 3250 rpm,

1-1/2 hp, jet pump motor, and used a precision backing plate made by

"Shopsmith",

which was also new.

It has a 5/8" motor shaft hole, and the platen is about 1/8"

thick.

It is not keyed to the shaft, just has a large set screw, so you need

to

have a 5/8" motor shaft with a flat side, or file one on it. I actually

filed

a rounded notch in the shaft, instead of a flat, to engage the set

screw

in order to make it more secure from loosening and sliding on the

shaft.

The platen is very precision made, and of high strength steel. When I

turned

it on for the first time I was amazed to see it rotate with virtually

no

wobble at all...perfectly flat running. I forged the handle from

a 3/8"

x 2" steel bar which I split lengthwise, and then punched and

shaped

to allow it to be attached directly by using the motor mounting bolts.

I

think that this 3/8" thick forging would be very difficult to make if

you

do not have a swage block. It is not easy even with a swage block.

Notice

the back end of the handle, which has a down dropped and rounded

partial

flange to prevent it sliding out of the hand. The handle is rock solid

and

secure in use. (Note:

The "Shopsmith" disk grinder

platen comes with a warning label stating not to spin it faster than

2000

rpm. I do not recommend you do so, as I am doing, unless you do your

own

engineering design calculations to determine if the steel

platen can

be rotated safely at the higher speed. I make no suggestion that it is

safe

to do so. If you decide to spin it at a higher than recommended speed, you

do so entirely at your own

risk.)

My Blacksmithing History, and My Forge

My interest

in blacksmith work started early in life when I lived in Okinawa. I

built

my first small "beehive" forge from clay, and was able to get metal hot

enough

to do some simple forging operations with it. I was only about 13 years

old

at the time. When I was 16, I built a bottom blown furnace which a

friend

and I used to melt iron to cast a simple cannon. The cannon was a grand

success,

capable of shooting through 16 inches of Madrona tree in my back yard!

My

father was not impressed.

My interest

in blacksmith work started early in life when I lived in Okinawa. I

built

my first small "beehive" forge from clay, and was able to get metal hot

enough

to do some simple forging operations with it. I was only about 13 years

old

at the time. When I was 16, I built a bottom blown furnace which a

friend

and I used to melt iron to cast a simple cannon. The cannon was a grand

success,

capable of shooting through 16 inches of Madrona tree in my back yard!

My

father was not impressed.

Following the cannon

episode, my "talents" were to lay hidden for many years until a good

friend

asked me if I wanted to help him build a simple

forge

to heat treat a large block of steel

with. I thought

it sounded interesting, and so started an epic that culminated in the

construction of the forge you see in the picture at the top of this

page,

and eventually with the construction of my blacksmith

shop. The construction of the forge took seven years on a

weekend, part

time, basis, but the results were worth all of it. The forge has an

expandable tuyere enabling

me to maintain a fire in

a small radius, or lengthen the tuyere to as much as 17 inches for

large

heats. The tuyere block is almost three inches thick, so no matter how

hot

the fire, or how long I maintain it, the tuyere never gets hot enough

to

burn.

Following the cannon

episode, my "talents" were to lay hidden for many years until a good

friend

asked me if I wanted to help him build a simple

forge

to heat treat a large block of steel

with. I thought

it sounded interesting, and so started an epic that culminated in the

construction of the forge you see in the picture at the top of this

page,

and eventually with the construction of my blacksmith

shop. The construction of the forge took seven years on a

weekend, part

time, basis, but the results were worth all of it. The forge has an

expandable tuyere enabling

me to maintain a fire in

a small radius, or lengthen the tuyere to as much as 17 inches for

large

heats. The tuyere block is almost three inches thick, so no matter how

hot

the fire, or how long I maintain it, the tuyere never gets hot enough

to

burn.

Inside the forge

there is a swing arm crane for handling lead pots, or brass melting

ladles.

The forge has a hand cranked blower,

and an electric

blower with an air dump

to vary the blast when

using the powered blower. Also, the bed of the forge is fully

lined with fire brick, so

even after a full day of

operation you can still place your hand on the outside with little

discomfort.

The only down side of this design is the lack of a clinker breaker. To

have

the variable tuyere I had to give up that convenience. That means that

I

have to open up the fire periodically to lift out the clinker and clear

the

air holes. If my timing is good, the clinker will lift out all in one

big

piece, making the operation quick and clean. It doesn't always work

that

way however.

Inside the forge

there is a swing arm crane for handling lead pots, or brass melting

ladles.

The forge has a hand cranked blower,

and an electric

blower with an air dump

to vary the blast when

using the powered blower. Also, the bed of the forge is fully

lined with fire brick, so

even after a full day of

operation you can still place your hand on the outside with little

discomfort.

The only down side of this design is the lack of a clinker breaker. To

have

the variable tuyere I had to give up that convenience. That means that

I

have to open up the fire periodically to lift out the clinker and clear

the

air holes. If my timing is good, the clinker will lift out all in one

big

piece, making the operation quick and clean. It doesn't always work

that

way however.

The forge pan is

constructed out of 1/4 inch steel plate which I lined

with

fire brick when the metalwork of the forge was complete.

Following completion

of the basic forge, I used

the unit for several years

until I found that the smoke was having an adverse affect on my health.

I

decided to construct a hood that would protect me from the worst of the

smoke.

The first version had an 8 inch diameter chimney, which was not big

enough

to handle the heavier smoke during some start-ups. So, I cut out the

thimble

and fabricated one 10 inch in diameter, and the chimney finally worked

perfectly.

If you would like to see a high resolution image of the finished forge,

please

click here.

The forge pan is

constructed out of 1/4 inch steel plate which I lined

with

fire brick when the metalwork of the forge was complete.

Following completion

of the basic forge, I used

the unit for several years

until I found that the smoke was having an adverse affect on my health.

I

decided to construct a hood that would protect me from the worst of the

smoke.

The first version had an 8 inch diameter chimney, which was not big

enough

to handle the heavier smoke during some start-ups. So, I cut out the

thimble

and fabricated one 10 inch in diameter, and the chimney finally worked

perfectly.

If you would like to see a high resolution image of the finished forge,

please

click here.

While I was building

the forge, I was also building an "anvil work station." It evolved into

an

anvil block welded on a heavy steel plate "work surface," i.e. small

table.

I also built a hold fast, or third hand, to help me work alone. I later

lucked

into finding several very nice anvils, one of which you can see in the

picture. In the process I

also collected a lot of

other equipment, including five excellent post vises

(including a pristine 8" Colombian post

vise), two brand

new pairs of blacksmith's shears,

a fine

post drill, and numerous

other odds and ends. I have

continued to build some of the many tools needed in this work, with a

goal

of eventually spending my time in decorative iron work.

While I was building

the forge, I was also building an "anvil work station." It evolved into

an

anvil block welded on a heavy steel plate "work surface," i.e. small

table.

I also built a hold fast, or third hand, to help me work alone. I later

lucked

into finding several very nice anvils, one of which you can see in the

picture. In the process I

also collected a lot of

other equipment, including five excellent post vises

(including a pristine 8" Colombian post

vise), two brand

new pairs of blacksmith's shears,

a fine

post drill, and numerous

other odds and ends. I have

continued to build some of the many tools needed in this work, with a

goal

of eventually spending my time in decorative iron work.

The project was far

more successful than I ever expected it to be. I have used the forge

for

my foundry work, easily melting large crucibles of aluminum. I have

also

taken heats on several large pieces of iron weighing 100 pounds or

more,

with no problems encountered, other than those related to the handling

of

massive blocks of red hot metal.

The project was far

more successful than I ever expected it to be. I have used the forge

for

my foundry work, easily melting large crucibles of aluminum. I have

also

taken heats on several large pieces of iron weighing 100 pounds or

more,

with no problems encountered, other than those related to the handling

of

massive blocks of red hot metal.

I have now had the

time to get into some very fine metal work, and the future looks very

bright.

This "hobby" has now evolved into a small business, and its growing

rapidly.

I still have a ways to go before I am showing a net positive cash

balance,

based on what I have put into my shop and tools, but that

point is getting

closer every day.

I have now had the

time to get into some very fine metal work, and the future looks very

bright.

This "hobby" has now evolved into a small business, and its growing

rapidly.

I still have a ways to go before I am showing a net positive cash

balance,

based on what I have put into my shop and tools, but that

point is getting

closer every day.

I was very lucky

several years ago to find a large amount of old "wrought iron", some of

it

in massive sections, at some of our old Idaho mining sites. I collected

as

much as I could, and am still finding more on occasion. I want to use

this

hundred year old iron for projects that would be of special interest to

people.

So far, about all I have made out of it is a series of leaves for key

chains.

They were received warmly, and are still being used by many of my

friends.

I don't know if it is the workmanship or the historical interest of the

metal

that has made them successful.

I was very lucky

several years ago to find a large amount of old "wrought iron", some of

it

in massive sections, at some of our old Idaho mining sites. I collected

as

much as I could, and am still finding more on occasion. I want to use

this

hundred year old iron for projects that would be of special interest to

people.

So far, about all I have made out of it is a series of leaves for key

chains.

They were received warmly, and are still being used by many of my

friends.

I don't know if it is the workmanship or the historical interest of the

metal

that has made them successful.

Besides my big coal

forge, I have another small open pan riveter's

forge

that is in excellent condition, and that I have restored to look brand

new

for demonstration forge work. I also have completed the building of a

four

burner propane forge that will allow almost "instant on" forging with

its

Kaowool liner and reflective coating of ITC-100. The convenience of

having

an "instant on" forge fire is wonderful for short forge sessions in the

evening.

Being a 24" long cylindrical forge, it also allows me to heat much

longer

sections of iron uniformly than was possible for me in the past. This

is

more of a bladesmith's forge, and its ability to easily forge weld is a

very

welcome addition. Gas forge welding is far easier than coal forge

welding.

Besides my big coal

forge, I have another small open pan riveter's

forge

that is in excellent condition, and that I have restored to look brand

new

for demonstration forge work. I also have completed the building of a

four

burner propane forge that will allow almost "instant on" forging with

its

Kaowool liner and reflective coating of ITC-100. The convenience of

having

an "instant on" forge fire is wonderful for short forge sessions in the

evening.

Being a 24" long cylindrical forge, it also allows me to heat much

longer

sections of iron uniformly than was possible for me in the past. This

is

more of a bladesmith's forge, and its ability to easily forge weld is a

very

welcome addition. Gas forge welding is far easier than coal forge

welding.

As I mentioned above,

I now have an 8" Colombian post vise.

I obtained it

as a result of a contact I made at the Sumpter flea market in Oregon. I

also

obtained a fine post drill

for $20 from the same fellow!

After cleaning it up I fitted it with a new 1/2" chuck, and it has

become

one of my most appreciated tools. I was amazed at how efficient the

drill

is. It can easily push a half inch bit through 1/4" plate in a minute

or

so, without a pilot hole! The post drill still has the original paint,

and

apparently had never been used, as the quill has no play at all.

As I mentioned above,

I now have an 8" Colombian post vise.

I obtained it

as a result of a contact I made at the Sumpter flea market in Oregon. I

also

obtained a fine post drill

for $20 from the same fellow!

After cleaning it up I fitted it with a new 1/2" chuck, and it has

become

one of my most appreciated tools. I was amazed at how efficient the

drill

is. It can easily push a half inch bit through 1/4" plate in a minute

or

so, without a pilot hole! The post drill still has the original paint,

and

apparently had never been used, as the quill has no play at all.

Another

post drill came into my shop that is even more surprising. It

is in superb

condition, no slop in the bearings, has a fine new "Ridgid" three jaw

chuck,

and even has the original paint on the black wooden handle. On top of

all

that it is a large one, fully twice as big as the above mentioned

drill,

has two speeds, and drills a half inch hole effortlessly. A friend

offered

it to me for $25, and of course I grabbed it. It had one defect, it had

the

quill advance arm broken off, and the part that engages the top ratchet

quill

advance wheel was missing. Luckily the lower half that rides the cam

was

still present. I forged the missing part, which involved making a split

fork

mounting bracket for the little ratchet pawl that engages the ratchet

wheel,

and after brazing it in place and painting it, the part looks

completely

original and works perfectly. It is now my main drill. The image

indicates

the part that I had to rebuild. Once in a while things come along when

you

are least expecting them. :-)

Another

post drill came into my shop that is even more surprising. It

is in superb

condition, no slop in the bearings, has a fine new "Ridgid" three jaw

chuck,

and even has the original paint on the black wooden handle. On top of

all

that it is a large one, fully twice as big as the above mentioned

drill,

has two speeds, and drills a half inch hole effortlessly. A friend

offered

it to me for $25, and of course I grabbed it. It had one defect, it had

the

quill advance arm broken off, and the part that engages the top ratchet

quill

advance wheel was missing. Luckily the lower half that rides the cam

was

still present. I forged the missing part, which involved making a split

fork

mounting bracket for the little ratchet pawl that engages the ratchet

wheel,

and after brazing it in place and painting it, the part looks

completely

original and works perfectly. It is now my main drill. The image

indicates

the part that I had to rebuild. Once in a while things come along when

you

are least expecting them. :-)

Another

drill press that may be of

interest is one that I built,

which is patterned after an early 1800's press that uses a large ACME

screw

to apply crowd pressure to a heavy forged brace. The press uses spade

bits,

which I forge myself. Although not a speedy operation, it is a very

easy

drill to use, and can easily drill 1/2" to 1" holes through heavy

plate.

I was really amazed the first time that I used the press how easily it

operated.

I also quickly learned that the angles on the spade bits are very

critical

or they will drill triangular holes instead of round. I later lucked

into

finding a second perfect hand forged brace at the Sumpter flea market

for

$1 that is much heavier than the one I forged. It displays no flexure

in

use, even when very heavy crowd force is applied with the ACME screw

feed.

Another

drill press that may be of

interest is one that I built,

which is patterned after an early 1800's press that uses a large ACME

screw

to apply crowd pressure to a heavy forged brace. The press uses spade

bits,

which I forge myself. Although not a speedy operation, it is a very

easy

drill to use, and can easily drill 1/2" to 1" holes through heavy

plate.

I was really amazed the first time that I used the press how easily it

operated.

I also quickly learned that the angles on the spade bits are very

critical

or they will drill triangular holes instead of round. I later lucked

into

finding a second perfect hand forged brace at the Sumpter flea market

for

$1 that is much heavier than the one I forged. It displays no flexure

in

use, even when very heavy crowd force is applied with the ACME screw

feed.

The gentleman I bought

the smaller post drill, and a 4" post vise, from mentioned that he had

a

big post vise at his ranch in

Washington. I was

interested, so we exchanged information. A few days later he contacted

me,

and I arranged to come up and have a look at it. After a 325 mile drive

I

arrived at his ranch to a warm welcome. After coffee and cookies, he

took

me out to show me the vise. At first the heavy coating of mud and horse

dung

concealed the condition of the vise underneath. After a little

investigation

I bought it, and returned the 325 miles to my home in Boise. It was not

until

several days later that I cleaned it up and discovered what a treasure

I

had come upon. It is now all cleaned up, and gleams in a coating of

oil,

waiting to be mounted. I feel extremely lucky to have obtained such a

massive

vise in such excellent condition. The jaws do not even have any hammer

marks

on them. Apparently it is virtually brand new and unused, and just sat

in

the old barn for the last 100 years or so. BTW, the little girl next to

the

vise in the image is my daughter Natalie when she was 4 years old.

The gentleman I bought

the smaller post drill, and a 4" post vise, from mentioned that he had

a

big post vise at his ranch in

Washington. I was

interested, so we exchanged information. A few days later he contacted

me,

and I arranged to come up and have a look at it. After a 325 mile drive

I

arrived at his ranch to a warm welcome. After coffee and cookies, he

took

me out to show me the vise. At first the heavy coating of mud and horse

dung

concealed the condition of the vise underneath. After a little

investigation

I bought it, and returned the 325 miles to my home in Boise. It was not

until

several days later that I cleaned it up and discovered what a treasure

I

had come upon. It is now all cleaned up, and gleams in a coating of

oil,

waiting to be mounted. I feel extremely lucky to have obtained such a

massive

vise in such excellent condition. The jaws do not even have any hammer

marks

on them. Apparently it is virtually brand new and unused, and just sat

in

the old barn for the last 100 years or so. BTW, the little girl next to

the

vise in the image is my daughter Natalie when she was 4 years old.

My 4-Burner Propane Forge Design

I have completed

the construction of a propane forge

using the burners

described in the next section below. It utilizes 4 burners in an

asymmetric

burner arrangement. It also has an easily movable "Kaowool board" back

wall

that allows for instant adjustment of the length of the forge chamber

to

achieve the highest temperatures possible for the given work placed

into

the forge. This is a naturally aspirated forge, no blowers, that easily

reaches

welding temperatures, and above, and I am at an elevation of 2300 feet.

I have completed

the construction of a propane forge

using the burners

described in the next section below. It utilizes 4 burners in an

asymmetric

burner arrangement. It also has an easily movable "Kaowool board" back

wall

that allows for instant adjustment of the length of the forge chamber

to

achieve the highest temperatures possible for the given work placed

into

the forge. This is a naturally aspirated forge, no blowers, that easily

reaches

welding temperatures, and above, and I am at an elevation of 2300 feet.

Additional

Image #1

Additional

Image #2

Close-up

of Idle/Full Valve Arrangement

or

Idle/Full Schematic

Diagram

For a far more

economical forge, you should use an "idle/full" valve arrangement so

that you can instantly drop your forge to a quiet idle when you are at

the anvil, or tending to some other chore, such as a phone call, etc.

When you return to the forge, a simple quarter turn of the lower ball

valve instantly brings the forge back up to full heat. You will

discover that the forge will not lose its operating temperature when in

idle mode either. The idle/full schematic

diagram is self explanatory, and you can easily figure out

how to adjust the upper and lower gas pressures by using the needle

valve and regulator for your particular needs when starting your day at

the forge. Although the schematic calls for 1/8" plumbing, you may want

to use 3/8" for everything except the little bypass that has the needle

valve in it. If you are using more then one burner, the larger diameter

plumbing will provide a better fuel flow with less pressure drop.

(Thanks goes to Rex Price of Hybridburners.com

for the excellent Idle/Full schematic diagram.)

For a far more

economical forge, you should use an "idle/full" valve arrangement so

that you can instantly drop your forge to a quiet idle when you are at

the anvil, or tending to some other chore, such as a phone call, etc.

When you return to the forge, a simple quarter turn of the lower ball

valve instantly brings the forge back up to full heat. You will

discover that the forge will not lose its operating temperature when in

idle mode either. The idle/full schematic

diagram is self explanatory, and you can easily figure out

how to adjust the upper and lower gas pressures by using the needle

valve and regulator for your particular needs when starting your day at

the forge. Although the schematic calls for 1/8" plumbing, you may want

to use 3/8" for everything except the little bypass that has the needle

valve in it. If you are using more then one burner, the larger diameter

plumbing will provide a better fuel flow with less pressure drop.

(Thanks goes to Rex Price of Hybridburners.com

for the excellent Idle/Full schematic diagram.)

The forge uses 2"

of Kaowool coated with

ITC-100

"black body

radiator" ceramic coating material made by

"International Technical Ceramics Corporation." This material radiates

98% of all the IR that it absorbs

back to the work. This creates a hotter and more economical running

forge

with a cooler shell.

The forge uses 2"

of Kaowool coated with

ITC-100

"black body

radiator" ceramic coating material made by

"International Technical Ceramics Corporation." This material radiates

98% of all the IR that it absorbs

back to the work. This creates a hotter and more economical running

forge

with a cooler shell.

The floor of the

forge consists of a half of a 1" thick, high alumina, kiln shelf

supported

on six kiln shelf posts, each 1" long. The hollow kiln shelf posts are

held

in place by 3/8" diameter by 1/2" steel pins blind welded into the

forge

shell. The posts sit over the pins. With this arrangement a full

circumference

1" layer of Kaowool can be installed which runs right under the floor

plate,

thus increasing the insulation and efficiency of the system. A second

layer

of Kaowool runs from one side of the floor plate up and around to the

other

side.

The floor of the

forge consists of a half of a 1" thick, high alumina, kiln shelf

supported

on six kiln shelf posts, each 1" long. The hollow kiln shelf posts are

held

in place by 3/8" diameter by 1/2" steel pins blind welded into the

forge

shell. The posts sit over the pins. With this arrangement a full

circumference

1" layer of Kaowool can be installed which runs right under the floor

plate,

thus increasing the insulation and efficiency of the system. A second

layer

of Kaowool runs from one side of the floor plate up and around to the

other

side.

The front

opening of the forge is closed with special ultra light weight, high

"R",

fire-bricks. I have a brick shelf constructed which the bricks rest on.

To

prevent accidentally snagging a brick off the shelf while removing work

from

the forge I have two additional spring keeper rods that hold the bricks

to

the face of the forge. The bricks can be moved to adjust the opening as

required

by different sized work pieces. With the movable back wall, and

adjustable

brick front end, the forge has very great versatility in its use and

configuration.

The front

opening of the forge is closed with special ultra light weight, high

"R",

fire-bricks. I have a brick shelf constructed which the bricks rest on.

To

prevent accidentally snagging a brick off the shelf while removing work

from

the forge I have two additional spring keeper rods that hold the bricks

to

the face of the forge. The bricks can be moved to adjust the opening as

required

by different sized work pieces. With the movable back wall, and

adjustable

brick front end, the forge has very great versatility in its use and

configuration.

If you have additional

questions after viewing the burner drawing and document below, please

feel

free to e-mail me with them. I would be more than glad to help you with

any

questions, or in helping you design your own forge, propane or coal.

If you have additional

questions after viewing the burner drawing and document below, please

feel

free to e-mail me with them. I would be more than glad to help you with

any

questions, or in helping you design your own forge, propane or coal.

Update:

I made two important changes to my big gas forge that should be of

interest

if you want to build one. I retrofitted two of my burners, #1 &

#2, to

the Bordeaux modification, and additionally used a new method to lock

the

jet tube which requires no drilling or tapping of holes. I also added

an

axial choke to these burners at the same time. This first

image shows the details of the burner modification, and the

second image shows both

burners in place and in

use, and also allows comparison to my old burner style on burners 3 and

4.

For more details of this burner modification please go to my

burner design page and

look under "Chokes".

Update:

I made two important changes to my big gas forge that should be of

interest

if you want to build one. I retrofitted two of my burners, #1 &

#2, to

the Bordeaux modification, and additionally used a new method to lock

the

jet tube which requires no drilling or tapping of holes. I also added

an

axial choke to these burners at the same time. This first

image shows the details of the burner modification, and the

second image shows both

burners in place and in

use, and also allows comparison to my old burner style on burners 3 and

4.

For more details of this burner modification please go to my

burner design page and

look under "Chokes".

The other change

was to my movable back wall and is of equal importance and utility. I

cut

a small, 1-1/2" wide by 1-1/2" high, opening in the bottom center of

the

Kaowool board at floor level to allow long work to pass though the

wall.

The opening tapers inwards, losing about 1/2" of its width at the top

of

the opening. To do this I had to fabricate new stainless steel supports

to

keep the back wall vertical but allowing clearance for the opening.

This

allows the wall to be moved forward to create a very small chamber

volume,

heating only a small portion of an otherwise long item, and

preventing

scale formation on those portions not heated. In the past I

had to

move the back wall back for long work, which heated the entire object,

even

if I only had to actually work a small section in its center. I made

this

change so that I could obtain better finishes on things like these

snakes, made from railroad

spikes...also

shown.

The other change

was to my movable back wall and is of equal importance and utility. I

cut

a small, 1-1/2" wide by 1-1/2" high, opening in the bottom center of

the

Kaowool board at floor level to allow long work to pass though the

wall.

The opening tapers inwards, losing about 1/2" of its width at the top

of

the opening. To do this I had to fabricate new stainless steel supports

to

keep the back wall vertical but allowing clearance for the opening.

This

allows the wall to be moved forward to create a very small chamber

volume,

heating only a small portion of an otherwise long item, and

preventing

scale formation on those portions not heated. In the past I

had to

move the back wall back for long work, which heated the entire object,

even

if I only had to actually work a small section in its center. I made

this

change so that I could obtain better finishes on things like these

snakes, made from railroad

spikes...also

shown.

One additional

operating tip, for multiple burner forges, that you need to be aware of

regards

how to handle the individual burners while the forge is running. If you

leave

the burners open, and use only one or two, the others will act like

chimneys

and quickly become extremely hot, damaging them. You only have to stuff

a

small wad of paper towel into the throat of any unused burners to

prevent

this, and when you wish to add a burner, just pull the paper out with a

set

of needle nose pliers, and immediately open the gas valve for that

burner.

You do not need to shut down the forge to add or remove burners from

operation

while the forge is running. The heat in the forge will not even scorch

the

paper most of the time, although it will do so to a limited degree when

placing

the paper into the burner throat when the forge is running due to the

chimney

effect. Of course this technique only works if each burner has its own

individual

valve, a requirement in my opinion, if for no other reason than fuel

economy.

One additional

operating tip, for multiple burner forges, that you need to be aware of

regards

how to handle the individual burners while the forge is running. If you

leave

the burners open, and use only one or two, the others will act like

chimneys

and quickly become extremely hot, damaging them. You only have to stuff

a

small wad of paper towel into the throat of any unused burners to

prevent

this, and when you wish to add a burner, just pull the paper out with a

set

of needle nose pliers, and immediately open the gas valve for that

burner.

You do not need to shut down the forge to add or remove burners from

operation

while the forge is running. The heat in the forge will not even scorch

the

paper most of the time, although it will do so to a limited degree when

placing

the paper into the burner throat when the forge is running due to the

chimney

effect. Of course this technique only works if each burner has its own

individual

valve, a requirement in my opinion, if for no other reason than fuel

economy.

Originally

my four burner

asymmetric layout was intended to allow three equally spaced burners to

be

used close together, or three burners equally spaced but farther apart.

After

switching over to T-Rex burners I found that four burners are too many

for

the 24" length of the forge. I recommend you use only two or three

burners,

and a 14" diameter shell, so that you can install three inches of

Kaowool.

With three burners you can sill set them up to run two or three burners

equally

spaced, but never run all three at one time. I will be changing my

forge

over to use a 14" shell and three burners soon. Even

if you are

using Reil or EZ-Burners, use only two or three burners. The only time

I

can see that anyone might want to run all three burners at one time

would

be for bringing a long length of iron up to forge welding temperature

over

its full length. This may be of use when producing Damascus billets

employing

the "new" rolling method.

Originally

my four burner

asymmetric layout was intended to allow three equally spaced burners to

be

used close together, or three burners equally spaced but farther apart.

After

switching over to T-Rex burners I found that four burners are too many

for

the 24" length of the forge. I recommend you use only two or three

burners,

and a 14" diameter shell, so that you can install three inches of

Kaowool.

With three burners you can sill set them up to run two or three burners

equally

spaced, but never run all three at one time. I will be changing my

forge

over to use a 14" shell and three burners soon. Even

if you are

using Reil or EZ-Burners, use only two or three burners. The only time

I

can see that anyone might want to run all three burners at one time

would

be for bringing a long length of iron up to forge welding temperature

over

its full length. This may be of use when producing Damascus billets

employing

the "new" rolling method.

You

may also be interested in my single burner "Freon

Tank Mini-Forge." This little forge has been a very useful

addition to

my tools, and may be something that would be useful to you too.

You

may also be interested in my single burner "Freon

Tank Mini-Forge." This little forge has been a very useful

addition to

my tools, and may be something that would be useful to you too.

Some Propane Burner Designs

"The Reil Burner"

I strongly suggest you read the "Side-arm Burner" note at the bottom of this section

before deciding on a burner to build. It is the design I now recommend

for the guy who wants to build his own burner.

I have posted a

design modification to the

well known "Russ Vullo/Derry

Cook" propane burner (Aussie Burner) design that may interest you if

you

are going to build a forge. This burner will sustain an open air flame

with

input propane gas pressure as high as 54 psi! At that pressure the

flame

is blue for only 1-1/2", indicating an almost total burn at that point.

It

is a big jump forward from the older design. I also have a

FAQ available that

discusses the details for

constructing the burner, as well as details of the regulator and other

related

equipment. There is also a section included on tuning the burner, even

though

the information is available elsewhere. You are welcome to share this

information, but please leave all credits on the documents, both mine,

and

the ones for those smiths who did earlier work to help develop this

burner

in the past. They deserve credit too. Thank you.

I have posted a

design modification to the

well known "Russ Vullo/Derry

Cook" propane burner (Aussie Burner) design that may interest you if

you

are going to build a forge. This burner will sustain an open air flame

with

input propane gas pressure as high as 54 psi! At that pressure the

flame

is blue for only 1-1/2", indicating an almost total burn at that point.

It

is a big jump forward from the older design. I also have a

FAQ available that

discusses the details for

constructing the burner, as well as details of the regulator and other

related

equipment. There is also a section included on tuning the burner, even

though

the information is available elsewhere. You are welcome to share this

information, but please leave all credits on the documents, both mine,

and

the ones for those smiths who did earlier work to help develop this

burner

in the past. They deserve credit too. Thank you.

Note: Brian Boorman

has created an outstanding step by step pictorial web page showing the

complete

construction of a Reil Burner. If the line drawing linked above isn't

enough

information for you to work from, you may want to visit Brian's page.

Go

to

http://metalcast.boorman.us and

click the "Propane Burner" link. I want to thank Brian for his

outstanding

contribution to the metalworking community.

NOTE:

I have now included

an additional "EZ-Burner"

design that you may

find much easier to build. It eliminates the difficulty of doing the

flare

in the nozzle, and also eliminates three of the drilled and tapped

holes.

I am not including a drawing for this modification as it is not

necessary,

but I do have a burner image

that may be of use.

The "EZ-Burner" HTML document linked above should provide all the

information

you need to build this quick and easy burner. It should only require a

couple

of hours to complete it.... I would like to include one additional note

about

galvanized pipe. By all means do use it for your burner. It will not

get

hot enough to bother the galvanizing, except for the last 1-2 inches,

and

if it does, you are doing something wrong. Properly used, the burner

should

be cool enough to handle at all times, except for the 1" diameter

nozzle

piece at the end. The galvanizing will protect your burner from rust.

If

it does get hot enough at the end to burn off the coating, the tiny

amount

involved will not cause you any problems, and its a one time event.

NOTE:

I have now included

an additional "EZ-Burner"

design that you may

find much easier to build. It eliminates the difficulty of doing the

flare

in the nozzle, and also eliminates three of the drilled and tapped

holes.

I am not including a drawing for this modification as it is not

necessary,

but I do have a burner image

that may be of use.

The "EZ-Burner" HTML document linked above should provide all the

information

you need to build this quick and easy burner. It should only require a

couple

of hours to complete it.... I would like to include one additional note

about

galvanized pipe. By all means do use it for your burner. It will not

get

hot enough to bother the galvanizing, except for the last 1-2 inches,

and

if it does, you are doing something wrong. Properly used, the burner

should

be cool enough to handle at all times, except for the 1" diameter

nozzle

piece at the end. The galvanizing will protect your burner from rust.

If

it does get hot enough at the end to burn off the coating, the tiny

amount

involved will not cause you any problems, and its a one time event.

I have recently

added a very valuable image

which shows

how to judge your burner flame to determine if its running lean

(oxidizing),

neutral (best setting), or rich (safe for the iron but wastes fuel, is

low

in temperature, and can create a CO hazard). Credit goes to

Rupert Wenig for taking the series of images of

his Minimongo

Burner that I was able to assemble into this very useful composite

image.

The only thing that varies from image to image is the choke setting.

The

gas pressure was set at 10 psi for all images.

I have recently

added a very valuable image

which shows

how to judge your burner flame to determine if its running lean

(oxidizing),

neutral (best setting), or rich (safe for the iron but wastes fuel, is

low

in temperature, and can create a CO hazard). Credit goes to

Rupert Wenig for taking the series of images of

his Minimongo

Burner that I was able to assemble into this very useful composite

image.

The only thing that varies from image to image is the choke setting.

The

gas pressure was set at 10 psi for all images.

A suggestion that I

highly recommend to you is to use a 14T

Tweco

tip on your "Reil or EZ-Burner" jet tube, instead of just

drilling the

jet opening in the jet pipe wall. This tapered copper tip will produce

a

superior intake vacuum which will result in a much greater burner

output.

If you do decide to go this route, you should use a 2" diameter intake

bell,

instead of the smaller one, to allow it to draw in the additional

volume

of air it will require. You will also need to use a larger jet diameter

to

allow more gas to be injected into the burner, balancing the additional

air

intake, or it will run too lean. If you elect to use this

modification

please read the warning

section at the

top of the "Mongo Burner" section of my Design Page.

A suggestion that I

highly recommend to you is to use a 14T

Tweco

tip on your "Reil or EZ-Burner" jet tube, instead of just

drilling the

jet opening in the jet pipe wall. This tapered copper tip will produce

a

superior intake vacuum which will result in a much greater burner

output.

If you do decide to go this route, you should use a 2" diameter intake

bell,

instead of the smaller one, to allow it to draw in the additional

volume

of air it will require. You will also need to use a larger jet diameter

to

allow more gas to be injected into the burner, balancing the additional

air

intake, or it will run too lean. If you elect to use this

modification

please read the warning

section at the

top of the "Mongo Burner" section of my Design Page.

Here is a very

cleaver way to mount your axial

choke. You may

need to increase the bell to 2" diameter however in order to compensate

for

the additional obstructions in the throat of the bell. Mr. Bill has

eliminated

the additional short nipple and mounted the axial choke right in the

cast

iron bell. Contact "Mr.

Bill" if you

have any questions.

Here is a very

cleaver way to mount your axial

choke. You may

need to increase the bell to 2" diameter however in order to compensate

for

the additional obstructions in the throat of the bell. Mr. Bill has

eliminated

the additional short nipple and mounted the axial choke right in the

cast

iron bell. Contact "Mr.

Bill" if you

have any questions.

Note:

There is now a burner design you can

build more easily than either the Reil or EZ burners. The Side-arm

burner design has now been perfected, and I recommend it. It can't

match

the output and range of the impressive T-Rex family of burners shown

below,

but its still an excellent burner for any forge or furnace. I have the

latest

information and images available on my Design

Page under the Mongo burner heading. Be

sure you use the new

design that uses an enlarged intake bell....see the images I have

posted.

Premade Burners Are Now

Available

The "T-Rex" Family of Burners

There

is now a superb

new premade burner available for those who do not want to build their

own,

or for those who want the ultimate in both quality and BTU output.This

burner was selected by NASA for a secret project after they scoured the

world to find the hottest naturally aspirated propane burner available.

This

is

a turned, milled, and tuned, hybrid designed jet ejector burner

which has

to be experienced to be believed. For a complete description see the

T-Rex Burner page.

There

is now a superb

new premade burner available for those who do not want to build their

own,

or for those who want the ultimate in both quality and BTU output.This

burner was selected by NASA for a secret project after they scoured the

world to find the hottest naturally aspirated propane burner available.

This

is

a turned, milled, and tuned, hybrid designed jet ejector burner

which has

to be experienced to be believed. For a complete description see the

T-Rex Burner page.

Another

burner that you may want to consider, and part of the

developing T-Rex

family of burners, is the "Shorty Burner." This is a

miniturized T-Rex, and has

applications in places

where the T-Rex may not fit, or where this reduced sized burner would

be

more convenient. I have a Shorty

Burner Page available

if you would like more information.

Another

burner that you may want to consider, and part of the

developing T-Rex

family of burners, is the "Shorty Burner." This is a

miniturized T-Rex, and has

applications in places

where the T-Rex may not fit, or where this reduced sized burner would

be

more convenient. I have a Shorty

Burner Page available

if you would like more information.

You

may

go directly to

Rex's own Burner

page if you wish. He has a trouble-shooting page, and a price

sheet there,

as well as a short description of the burners he presently is

producing,

which now include several much larger burners than I have listed here.

I

will not keep his full listing of burners updated on this page now that

he

has this information available for you on his page. The

descriptions

for the T-Rex and Shorty burner I have here are more complete than what

you

will find on Rex's site, so you may want to read these first, and then

link

to his site. I have links to his site at the end of each of the above

linked

pages for your convenience also.

You

may

go directly to

Rex's own Burner

page if you wish. He has a trouble-shooting page, and a price

sheet there,

as well as a short description of the burners he presently is

producing,

which now include several much larger burners than I have listed here.

I

will not keep his full listing of burners updated on this page now that

he

has this information available for you on his page. The

descriptions

for the T-Rex and Shorty burner I have here are more complete than what

you

will find on Rex's site, so you may want to read these first, and then

link

to his site. I have links to his site at the end of each of the above

linked

pages for your convenience also.

Pine Ridge Burners' "Ribbon Burner"

This

is a new addition to my page, and is the only burner on my web site

that is not naturally aspirated. You can get this propane/natural gas

burner in a variety of lengths, from 4" square, up to 4" x 19". It is a

blown, double mixing chamber, burner that has an initial fuel/air

mixing chamber feeding the initially mixed gases through secondary

mixing jets into a second mixing/injection chamber on the back side of

the ceramic nozzle block. It achieves a very high degree of mixing,

resulting in a very efficient and complete burn. The gases then pass

through large diameter jet openings in the ceramic burner block into

the forge or furnace chamber. The only temperature limitation for this

burner system is the power of your blower. The more blower power you

have the more propane or natural gas you can feed it, and the hotter

your forge or furnace will be, surpassing forge welding temperature.

This is not an inexpensive system to set up. If you use all the various

associated air supply and safety hardware that goes with this burner

you can easily approach $1000. If you already have a high pressure

blower and other supporting safety hardware you can cut your costs

significantly. Based on base costs, and system complexity, the T-Rex

burner would be a logical choice for most smiths, but if you need

maximum BTU delivery at the highest possible temperatures, this burner

is an excellent choice.

This

is a new addition to my page, and is the only burner on my web site

that is not naturally aspirated. You can get this propane/natural gas

burner in a variety of lengths, from 4" square, up to 4" x 19". It is a

blown, double mixing chamber, burner that has an initial fuel/air

mixing chamber feeding the initially mixed gases through secondary

mixing jets into a second mixing/injection chamber on the back side of

the ceramic nozzle block. It achieves a very high degree of mixing,

resulting in a very efficient and complete burn. The gases then pass

through large diameter jet openings in the ceramic burner block into

the forge or furnace chamber. The only temperature limitation for this

burner system is the power of your blower. The more blower power you

have the more propane or natural gas you can feed it, and the hotter