©Golden Age Forge

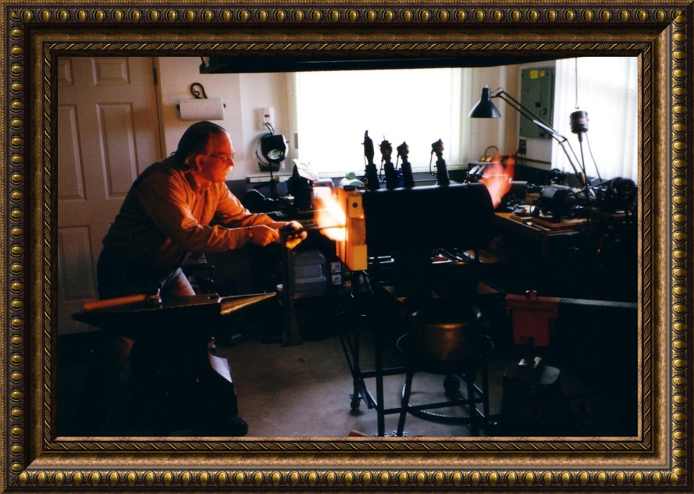

I am about to forge-weld a Spontoon pipe-ax head.

(This excellent image was taken by my apprentice, Kevin Brown)

A New Addition to My Shop - Out of this

world!

This is a 64 pound nickel-iron meteorite from Argentina that

fell about

4000 years ago!

Contact me by phone: (208)

462-4028

Note: Due to spam problems I no longer post my e-mail address.

![]()

![]() I provide the

following information as a service

to the blacksmithing community. Although the designs I employ in

building

my burners and forges are safe and reliable in the way that I use them,

the

same may not be the case for you. You assume all risk in

using this

information, or any other information on my site. Other

designs that

I have posted here have been submitted by other smiths, and I have no

experience

with most of them. Use care and good sense in using any of these

designs.

Get help from a knowledgeable smith if you are new to this work. Don't

take

chances, because these tools can cause injury, blindness, or even

death,

if used improperly. Also, be sure you are in a well ventilated space

(see the Nighthawk CO

& explosive gas

detector paragraph), or better yet, work outside.

Additionally, never

operate a forge that is connected directly to a propane tank located

near

a forge, or indoors. An emergency pressure valve release

could instantly

place you in the middle of a fireball. Follow all local codes regarding

indoor use of propane. I believe indoor use of a propane tank

violates

code everywhere in North America, and most of Europe. A new concern has

arisen

with the introduction of the "Mongo Burner Series." Please read

carefully

all the information in the separate "Safety

Warnings and Considerations" information which heads the

"Mongo Burner

Series" section. Thank you.

I provide the

following information as a service

to the blacksmithing community. Although the designs I employ in

building

my burners and forges are safe and reliable in the way that I use them,

the

same may not be the case for you. You assume all risk in

using this

information, or any other information on my site. Other

designs that

I have posted here have been submitted by other smiths, and I have no

experience

with most of them. Use care and good sense in using any of these

designs.

Get help from a knowledgeable smith if you are new to this work. Don't

take

chances, because these tools can cause injury, blindness, or even

death,

if used improperly. Also, be sure you are in a well ventilated space

(see the Nighthawk CO

& explosive gas

detector paragraph), or better yet, work outside.

Additionally, never

operate a forge that is connected directly to a propane tank located

near

a forge, or indoors. An emergency pressure valve release

could instantly

place you in the middle of a fireball. Follow all local codes regarding

indoor use of propane. I believe indoor use of a propane tank

violates

code everywhere in North America, and most of Europe. A new concern has

arisen

with the introduction of the "Mongo Burner Series." Please read

carefully

all the information in the separate "Safety

Warnings and Considerations" information which heads the

"Mongo Burner

Series" section. Thank you.

![]() An

additional item that should be of interest to you is

obtaining an

explosive gas/CO detector for your working space.

Mark Manley, of

"Manley Metal Works,"

Silverton, Oregon, provided a short piece of very important information

in

the Winter 2000 issue of "Hot Iron News" that I think needs to be

passed

on to a wider audience. There is a very reasonably priced digital

read-out

combination explosive gas and CO detector available in local hardware,

building

supply, and other stores. I was concerned about having a CO monitor in

my

shop, even though I have a very efficient induced draft hood in my

shop.

The detector is made by

"Kidde Safety"

and

is called the "Nighthawk." I will not go into the

specs for the instrument

here, they are available on their web site, but I will say that it is a

very

finely designed and built instrument. It runs on 110 VAC, and has a 12

VDC

back-up. It plugs directly into an outlet, or the transformer plug

detaches

for remote mounting up to 6' from the plug. You can easily check your

CO

level with a quick glance at the digital read-out, and if it detects

any

kind of flammable gas it will instantly sound an audible alarm, and the

word

"Gas" will show on the digital display. If it detects CO, it will sound

a

different audible alarm and display the PPM level. Also, you will know

it's

operating because the blinking decimal point in the digital read-out

indicates

it's operating and sampling the air in your shop.

An

additional item that should be of interest to you is

obtaining an

explosive gas/CO detector for your working space.

Mark Manley, of

"Manley Metal Works,"

Silverton, Oregon, provided a short piece of very important information

in

the Winter 2000 issue of "Hot Iron News" that I think needs to be

passed

on to a wider audience. There is a very reasonably priced digital

read-out

combination explosive gas and CO detector available in local hardware,

building

supply, and other stores. I was concerned about having a CO monitor in

my

shop, even though I have a very efficient induced draft hood in my

shop.

The detector is made by

"Kidde Safety"

and

is called the "Nighthawk." I will not go into the

specs for the instrument

here, they are available on their web site, but I will say that it is a

very

finely designed and built instrument. It runs on 110 VAC, and has a 12

VDC

back-up. It plugs directly into an outlet, or the transformer plug

detaches

for remote mounting up to 6' from the plug. You can easily check your

CO

level with a quick glance at the digital read-out, and if it detects

any

kind of flammable gas it will instantly sound an audible alarm, and the

word

"Gas" will show on the digital display. If it detects CO, it will sound

a

different audible alarm and display the PPM level. Also, you will know

it's

operating because the blinking decimal point in the digital read-out

indicates

it's operating and sampling the air in your shop.

![]() I bought one of

these

instruments for my shop, and was so impressed with it that I went down

and

bought a second one for my home, which has natural gas heat, gas hot

water,

and a natural gas fireplace insert. I priced CO detectors on the

McMaster-Carr

web site, and they alone were $170, where this combination instrument

is

only $59 at my local Home Depot. Considering how deadly CO can be, this

instrument is very inexpensive, well worth the investment, and it may

well

save your life. After Mark installed his "Nighthawk," he discovered

that

he had been exposing himself to CO levels of 30-160 PPM for a long time

while

running his forge! Thanks for the tip Mark.

I bought one of

these

instruments for my shop, and was so impressed with it that I went down

and

bought a second one for my home, which has natural gas heat, gas hot

water,

and a natural gas fireplace insert. I priced CO detectors on the

McMaster-Carr

web site, and they alone were $170, where this combination instrument

is

only $59 at my local Home Depot. Considering how deadly CO can be, this

instrument is very inexpensive, well worth the investment, and it may

well

save your life. After Mark installed his "Nighthawk," he discovered

that

he had been exposing himself to CO levels of 30-160 PPM for a long time

while

running his forge! Thanks for the tip Mark.

Note: There has been a recall of Kidde Safety "Nighthawk" gas and CO detectors. This does not affect any detectors sold after the date that I posted the above information, however you may check your unit by going to http://www.cpsc.gov/cpscpub/prerel/prhtml99/99082.html.

A Word About Obtaining My Help

![]() I am no longer

able to offer my support to help solve problems you may have with your

burners or forge. I have reached the point that something has to give.

Two to three hours a night answering questions has brought my metal

working each evening of the week to a stand still. I will continue to

update my blacksmithing pages, and will now also have the time to clean

out all the outdated and conflicting information in my pages, however,

I will no longer be able to troubleshoot your system. I still want to

receive your e-mails if they do not pertain to forge or burner

problems. If you build your burner to the design specs and information

shown and discussed on my pages, including in the Troubleshooting

Document and FAQ, your burner should work well. If it doesn't, then its

not built correctly, and you will need to make some adjustments after

looking through the available information. The best thing to look at

when fine tuning your burner are the various flame

images I have posted. If yours looks like these images, you have it

right. Here are a few helpful links.

I am no longer

able to offer my support to help solve problems you may have with your

burners or forge. I have reached the point that something has to give.

Two to three hours a night answering questions has brought my metal

working each evening of the week to a stand still. I will continue to

update my blacksmithing pages, and will now also have the time to clean

out all the outdated and conflicting information in my pages, however,

I will no longer be able to troubleshoot your system. I still want to

receive your e-mails if they do not pertain to forge or burner

problems. If you build your burner to the design specs and information

shown and discussed on my pages, including in the Troubleshooting

Document and FAQ, your burner should work well. If it doesn't, then its

not built correctly, and you will need to make some adjustments after

looking through the available information. The best thing to look at

when fine tuning your burner are the various flame

images I have posted. If yours looks like these images, you have it

right. Here are a few helpful links.

Note: If you e-mail me, please be sure your e-mail in "txt" (text) format, not html. I am now averaging two to three virused e-mails each time I download my e-mail, so I have to be very careful. If your e-mail is not in "txt" format I will most likely delete your e-mail without opening it in order to protect from possible virus infection. It's certainly sad that we have idiots in our society that feel they must cause such problems.

Forge & Burner Troubleshooting Document

1) T-Rex Flame Image - Ideal Neutral Flame

2) Side-arm Burner Flame Using Temporary Cast Iron Test Nozzle - Slightly Reducing Flame

3) Another Flame Image - Oxidizing Flame

![]() The bottom three

flame images give you views of burner flames adjusted to 1) neutral, 2)

slightly reducing, and 3) strongly oxidizing. The burners have nothing

to do with it, just the choke settings. All of these images could have

been done with the T-Rex, or Side-arm burners. At your high end gas

pressure, if you have achieved a flame similar to the oxidizing flame

shown in the bottom image, #3, you will then have full control over the

burner flame across the full pressure range. This will allow you to

achieve oxidizing, neutral, or reducing, flames as needed by simply

adjusting the choke. You will then have a properly functioning burner.

The bottom three

flame images give you views of burner flames adjusted to 1) neutral, 2)

slightly reducing, and 3) strongly oxidizing. The burners have nothing

to do with it, just the choke settings. All of these images could have

been done with the T-Rex, or Side-arm burners. At your high end gas

pressure, if you have achieved a flame similar to the oxidizing flame

shown in the bottom image, #3, you will then have full control over the

burner flame across the full pressure range. This will allow you to

achieve oxidizing, neutral, or reducing, flames as needed by simply

adjusting the choke. You will then have a properly functioning burner.

My Home

Page, & Pages on This Site

The Full Site Map - Lists All Pages on

This Site

![]() Visit my newest page, my "New Home and

Shop Page"

Visit my newest page, my "New Home and

Shop Page"![]()

Construction of the Freon Tank Mini-Forge

Note: "The Best of Theforge" is a collection of posts to "theforege" covering a great many blacksmithing subjects. It is made up of three separate files that are all hot linked and indexed. If you want to know what Superquench is, or the composition of a railroad spike, this is were you will find it. I have a lot of work in these files, I hope you will find my time was well spent.

The

Best of "Theforge" - a Zipped Download of All Three Files

-or-

The Best of Theforge -

Vol 1

Subject Index for the Design Pages

(Small font indicates a subsection.)

Page #1

The Reil & EZ Burners (These are the standard burners)

-Proper Nozzle Placement in the Forge

-Safety Warnings and Considerations for the Mongo Burners

-Micromongo & Nanomongo Burners

Page #2

Sources for Refractories, Burner Nozzles, & T-Rex Burners

-Obtaining Premade Burner Flares

Download the BTU Output Calculator

How Hot Can These Burners Get?

Some Additional Gas Forge Designs, 1 through 4

-Sandia Recuperative Forge Design

Additional Coal Forge Designs & Brake Drum Forges

A Preface for All Burners on This

Page

The "TWECO 14T Tip" Modification

![]() Work

by

Michael Porter

in Seattle has resulted

in a powerful modification that I recommend you apply to any of the

burner

designs on my pages. Instead of simply drilling the desired jet hole in

the

burner tube, you can achieve far superior results by drilling and

tapping

the jet hole location to take a 1/4"x 28 threaded "TWECO 14T" copper

tip,

available at your local welding supply shop. There are a variety of

these

tips in various jet diameters and external configurations available.

You

should try to obtain the Tweco tip configuration that measures 1-1/2"x

1/4,"

and has a long tapering nozzle tip. With this arrangement you can

easily

experiment with various tip openings simply by switching them as

desired.

Once you determine which tip performs best for your particular

application,

then you should silver solder it into place to prevent any possible gas

leakage

past the threads. Because of the high temperatures that the jet tip may

encounter, due to occasional chimney effects, you should not use any

other

lower temperature process, such as Teflon tape or soft lead solder.

Another

comment that applies if you are modifying the "Reil or EZ Burners"

regards

the bell diameter. The increased suction created by this tip

modification

will require that you increase the intake bell to a 2" diameter, or you

will

not get enough intake air to achieve a balanced burn.

Work

by

Michael Porter

in Seattle has resulted

in a powerful modification that I recommend you apply to any of the

burner

designs on my pages. Instead of simply drilling the desired jet hole in

the

burner tube, you can achieve far superior results by drilling and

tapping

the jet hole location to take a 1/4"x 28 threaded "TWECO 14T" copper

tip,

available at your local welding supply shop. There are a variety of

these

tips in various jet diameters and external configurations available.

You

should try to obtain the Tweco tip configuration that measures 1-1/2"x

1/4,"

and has a long tapering nozzle tip. With this arrangement you can

easily

experiment with various tip openings simply by switching them as

desired.

Once you determine which tip performs best for your particular

application,

then you should silver solder it into place to prevent any possible gas

leakage

past the threads. Because of the high temperatures that the jet tip may

encounter, due to occasional chimney effects, you should not use any

other

lower temperature process, such as Teflon tape or soft lead solder.

Another

comment that applies if you are modifying the "Reil or EZ Burners"

regards

the bell diameter. The increased suction created by this tip

modification

will require that you increase the intake bell to a 2" diameter, or you

will

not get enough intake air to achieve a balanced burn.

![]() An additional consideration that I need to mention, and which

is covered

in detail in the "Safety Warning"

section at the top

of the Mongo Burner information, regards UV radiation hazard. The Tweco

tips

increase the efficiency of the burners and their output temperature. In

the

Mongo burners the temperatures are up into the middle UV temperature

color

range, and it is possible to get "flash burns" from the light coming

out

of the forge. Be aware of this potential hazard with any burner you

modify

to use this tip. UV radiation is very damaging to eyes and

skin.

An additional consideration that I need to mention, and which

is covered

in detail in the "Safety Warning"

section at the top

of the Mongo Burner information, regards UV radiation hazard. The Tweco

tips

increase the efficiency of the burners and their output temperature. In

the

Mongo burners the temperatures are up into the middle UV temperature

color

range, and it is possible to get "flash burns" from the light coming

out

of the forge. Be aware of this potential hazard with any burner you

modify

to use this tip. UV radiation is very damaging to eyes and

skin.

Be sure to read the FAQ that goes with this design also.

![]() The

burner design above

is my modification to the well known "Aussie" burner, as

designed by

various smiths, some noted on the drawing. The "Reil Burner" is a

superior

burner in all respects. It will sustain a controlled flame with propane

gas

pressures of over 50 psi. The cost of building it averages about $5 US,

and

it is constructed of all "off the shelf" plumbing parts, available in

any

hardware store. The FAQ

explains its

construction, but is not a detailed step by step instruction

sheet.

It is a collection of suggestions and observations that will be of use

if

you decide to build one. This document also includes a section on

tuning

your burner.

The

burner design above

is my modification to the well known "Aussie" burner, as

designed by

various smiths, some noted on the drawing. The "Reil Burner" is a

superior

burner in all respects. It will sustain a controlled flame with propane

gas

pressures of over 50 psi. The cost of building it averages about $5 US,

and

it is constructed of all "off the shelf" plumbing parts, available in

any

hardware store. The FAQ

explains its

construction, but is not a detailed step by step instruction

sheet.

It is a collection of suggestions and observations that will be of use

if

you decide to build one. This document also includes a section on

tuning

your burner.

Note: Brian Boorman has created an outstanding step by step pictorial web page showing the complete construction of a Reil Burner. If the line drawing linked above isn't enough information for you to work from, you may want to visit Brian's page. Go to http://metalcast.boorman.us and click the "Propane Burner" link. I want to thank Brian for his outstanding contribution to the metalworking community.

![]() I have now included

an additional "EZ-Burner"

design that you may

find much easier to build. It eliminates the difficulty of doing the

flare

in the nozzle, and also eliminates three of the drilled and tapped

holes.

I am not including a drawing for this modification, as it is

not necessary,

but I do have an image of the burner

if you are

interested. The "EZ-Burner" HTML document linked above should provide

all

the information you need to build this quick and easy burner. It should

only

require a couple of hours to complete it. I would like to include one

additional

note about galvanized pipe. By all means do use it

for your burner.

It will not get hot enough to bother the galvanizing over most of its

length,

and if it does, you are doing something wrong. Properly used, the

burner

should be cool enough to handle at all times, except for the 1"

diameter

nozzle piece at the end. The galvanizing will protect your burner from

rust.

If it does get hot enough at the end to burn off the coating, the tiny

amount

involved will not cause you any problems. Also, do not use any pipe

joint

compound in the 3/4" joint, it's just not necessary, or of any value.

I have now included

an additional "EZ-Burner"

design that you may

find much easier to build. It eliminates the difficulty of doing the

flare

in the nozzle, and also eliminates three of the drilled and tapped

holes.

I am not including a drawing for this modification, as it is

not necessary,

but I do have an image of the burner

if you are

interested. The "EZ-Burner" HTML document linked above should provide

all

the information you need to build this quick and easy burner. It should

only

require a couple of hours to complete it. I would like to include one

additional

note about galvanized pipe. By all means do use it

for your burner.

It will not get hot enough to bother the galvanizing over most of its

length,

and if it does, you are doing something wrong. Properly used, the

burner

should be cool enough to handle at all times, except for the 1"

diameter

nozzle piece at the end. The galvanizing will protect your burner from

rust.

If it does get hot enough at the end to burn off the coating, the tiny

amount

involved will not cause you any problems. Also, do not use any pipe

joint

compound in the 3/4" joint, it's just not necessary, or of any value.

![]() I used four Reil

burners on my 24" long cylindrical

forge, but two

or three are all that is necessary, and two will probably be enough in most

cases.

I live at an elevation of 2300 feet, and I can easily weld with only

one

burner running at 6 psi propane pressure. They are also being used

successfully

at over 7000 feet elevation, and they can weld easily at that

elevation.

If you would like to see more images of this forge, please go to my

Forge and

Foundry Page.

Thank you.

I used four Reil

burners on my 24" long cylindrical

forge, but two

or three are all that is necessary, and two will probably be enough in most

cases.

I live at an elevation of 2300 feet, and I can easily weld with only

one

burner running at 6 psi propane pressure. They are also being used

successfully

at over 7000 feet elevation, and they can weld easily at that

elevation.

If you would like to see more images of this forge, please go to my

Forge and

Foundry Page.

Thank you.

![]() Use of Natural Gas:

You may use this burner for natural gas applications, but will have to

increase

the jet size in order to do so, and you will require 10-20 psi natural

gas

pressure. I know of at least two smiths currently using them with

natural

gas, but I do not know the jet diameters they are using. If you use

this

design for natural gas I would very much appreciate knowing your jet

size,

so I can add that information to this page so others may benefit from

your

work. Please contact me at (208) 462-4028. Thank you.

Use of Natural Gas:

You may use this burner for natural gas applications, but will have to

increase

the jet size in order to do so, and you will require 10-20 psi natural

gas

pressure. I know of at least two smiths currently using them with

natural

gas, but I do not know the jet diameters they are using. If you use

this

design for natural gas I would very much appreciate knowing your jet

size,

so I can add that information to this page so others may benefit from

your

work. Please contact me at (208) 462-4028. Thank you.

![]() I was contacted by

Ray Maiara

concerning the use of natural

gas. He is using natural gas at only 1/3 psi pressure, and has had to

go

to a very large "jet" size, about 1/8", and he is using a blower also,

so

this doesn't fit in the category of a venturi type burner. He has also

gone

to very large plumbing diameters, main feed of 1-1/2", and forge lead

in

of 3/4", to obtain as little restriction on the gas flow as possible.

If

you are considering the use of natural gas, contact your gas utility

and

ask them if they can provide you with a high pressure feed. My gas

company

will provide a high pressure tap off the household service, up to 80

psi,

and there is no additional service to pay for, nor is there any charge

for

the work to install the high pressure tap. I do have to buy the

additional

regulator however. It is worth your time to check into, since this

burner

will function with natural gas if sufficient pressure is available, but

again,

you will have to experiment with the jet diameter to find the proper

diameter,

given your available pressure. You must have enough pressure for the

venturi

action to operate correctly to draw the air into the bell. Remember

that

natural gas will not provide as much heat as propane, so your forge may

not

be able to forge-weld. If you use a blower and large jet diamerter you

will

be able to forge-weld easily.

I was contacted by

Ray Maiara

concerning the use of natural

gas. He is using natural gas at only 1/3 psi pressure, and has had to

go

to a very large "jet" size, about 1/8", and he is using a blower also,

so

this doesn't fit in the category of a venturi type burner. He has also

gone

to very large plumbing diameters, main feed of 1-1/2", and forge lead

in

of 3/4", to obtain as little restriction on the gas flow as possible.

If

you are considering the use of natural gas, contact your gas utility

and

ask them if they can provide you with a high pressure feed. My gas

company

will provide a high pressure tap off the household service, up to 80

psi,

and there is no additional service to pay for, nor is there any charge

for

the work to install the high pressure tap. I do have to buy the

additional

regulator however. It is worth your time to check into, since this

burner

will function with natural gas if sufficient pressure is available, but

again,

you will have to experiment with the jet diameter to find the proper

diameter,

given your available pressure. You must have enough pressure for the

venturi

action to operate correctly to draw the air into the bell. Remember

that

natural gas will not provide as much heat as propane, so your forge may

not

be able to forge-weld. If you use a blower and large jet diamerter you

will

be able to forge-weld easily.

![]() A properly adjusted

gas forge will have an air/gas mixture that will create a neutral, or

slightly

reducing, environment inside the forge. This is necessary to prevent

excessive

oxidation and scaling of the metal. With my burner design, the forge

environment

should meet that requirement if you use a #57 or #58 jet diameter. I

have

found that my forge needs no choke or intake air controls, and runs

with

a slightly reducing atmosphere as desired. If you want a very simple

and

extremely efficient burner, use the modified Aussie design. If you

build

it with the Bordeaux modification you will have the greatest

versatility

for adding a blower, or intake air controls (choke), if you feel you

need

them later.

A properly adjusted

gas forge will have an air/gas mixture that will create a neutral, or

slightly

reducing, environment inside the forge. This is necessary to prevent

excessive

oxidation and scaling of the metal. With my burner design, the forge

environment

should meet that requirement if you use a #57 or #58 jet diameter. I

have

found that my forge needs no choke or intake air controls, and runs

with

a slightly reducing atmosphere as desired. If you want a very simple

and

extremely efficient burner, use the modified Aussie design. If you

build

it with the Bordeaux modification you will have the greatest

versatility

for adding a blower, or intake air controls (choke), if you feel you

need

them later.

![]() There are an unlimited variety of forge designs, almost as

many designs as smiths, and most work well enough to do normal forging.

Probably fewer are hot enough to forge weld, but that can usually be

corrected with a little homework in proper forge design. However, every

now and again a forge comes along that is truly unique and worth

posting a picture of. The "Dragon Forge" by Wayne Coe is one of those

forges. Here are two image links to his asthetically as

well as functunally unique forge. Besides the obvious and beautifully forged dragon, notice the hinge

system on the forge, allowing Wayne to open his forge like a clam-shell. I need to

add that if you are interested in a "clam-shell" design, be aware that a

vertical lifting upper half will not expose you to the searing heat of

the interior of the forge like a hinged design will. Wayne does not

open his forge far enough to expose himself to the intense IR, so it

isn't an issue with him. And yes, those are twin 1" Rex burners

Wayne is firing his forge with. No problem attaining forge welding heat with this forge.

There are an unlimited variety of forge designs, almost as

many designs as smiths, and most work well enough to do normal forging.

Probably fewer are hot enough to forge weld, but that can usually be

corrected with a little homework in proper forge design. However, every

now and again a forge comes along that is truly unique and worth

posting a picture of. The "Dragon Forge" by Wayne Coe is one of those

forges. Here are two image links to his asthetically as

well as functunally unique forge. Besides the obvious and beautifully forged dragon, notice the hinge

system on the forge, allowing Wayne to open his forge like a clam-shell. I need to

add that if you are interested in a "clam-shell" design, be aware that a

vertical lifting upper half will not expose you to the searing heat of

the interior of the forge like a hinged design will. Wayne does not

open his forge far enough to expose himself to the intense IR, so it

isn't an issue with him. And yes, those are twin 1" Rex burners

Wayne is firing his forge with. No problem attaining forge welding heat with this forge.

![]() A lot of people ask

about what a proper burner flame should look like. Thanks to

Don Foreman,

I now have an excellent

image of a virtually perfect burner flame. The symmetry and zonation

are

as good as it gets. It is a an oxidizing flame. Your color intensities

may

not be quite as dramatic as in this image, but otherwise this is what

you

are attempting to achieve at your highest pressure setting, and which

you

can tune to neutral with the choke. Notice the perfect

symmetry of the

flame, which is an indication of a well centered jet, and the

"jet-engine"

like velocity the flame has. A flame that tends to burn to one side is

an

indication that the jet is not aligned correctly. You may click on the

image

for a larger view.

A lot of people ask

about what a proper burner flame should look like. Thanks to

Don Foreman,

I now have an excellent

image of a virtually perfect burner flame. The symmetry and zonation

are

as good as it gets. It is a an oxidizing flame. Your color intensities

may

not be quite as dramatic as in this image, but otherwise this is what

you

are attempting to achieve at your highest pressure setting, and which

you

can tune to neutral with the choke. Notice the perfect

symmetry of the

flame, which is an indication of a well centered jet, and the

"jet-engine"

like velocity the flame has. A flame that tends to burn to one side is

an

indication that the jet is not aligned correctly. You may click on the

image

for a larger view.

(Image courtesy of Don Foreman)

![]() Rupert Wenig has

provided

an excellent sequence of six

images of his Minimongo

Burner showing the effects on the burner flame of opening the choke. I

have

combined them into one image. The images on the right were taken

without

flash to show the flame characteristics more clearly. This is a very

instructional image, and should be extremely useful when you are tuning

any

kind of burner, not just the Mongo or Minimongo. You want to achieve a

neutral

flame as shown in the center image. Note:

The coupling that

Rupert is using for his flared nozzle has been machined out to have a

1:12

internal rate of flare...it is not just a coupling. Being cast iron it

would

also melt in an actual forge or furnace application. This is for test

purposes

only. Use stainless steel.

Rupert Wenig has

provided

an excellent sequence of six

images of his Minimongo

Burner showing the effects on the burner flame of opening the choke. I

have

combined them into one image. The images on the right were taken

without

flash to show the flame characteristics more clearly. This is a very

instructional image, and should be extremely useful when you are tuning

any

kind of burner, not just the Mongo or Minimongo. You want to achieve a

neutral

flame as shown in the center image. Note:

The coupling that

Rupert is using for his flared nozzle has been machined out to have a

1:12

internal rate of flare...it is not just a coupling. Being cast iron it

would

also melt in an actual forge or furnace application. This is for test

purposes

only. Use stainless steel.

T-Rex Flame Image - Ideal Neutral Flame

Side-arm Burner Flame Using Temporary Cast Iron Test Nozzle - Slightly Reducing Flame

Don's Flame Image - Oxidizing Flame

![]() Note about burner

nozzle placement in the forge:

Your burner nozzle should not enter the innermost layer of Kaowool. To

do

so will cause the nozzle to overheat and quickly degrade, or melt all

together.

Using a sharp knife, cut an "X" through both layers of Kaowool in front

of

the burner port, and from the outside, force the burner nozzle into the

forge

while spreading the Kaowool with your fingers to allow the nozzle to

squeeze

in. Stop when your have fully penetrated the outer layer of Kaowool.

Use

some kind of tapered plug, I use a turned hardwood plug, and from the

inside

of the chamber, force it through the X into the burner nozzle while

working

the Kaowool with your fingers to allow the plug to seat home against

and

inside the inner lip of the nozzle. The plug will need to have a

steeper

taper than the 1:12 that is inside the nozzle. By leaving the plug in

place

when the forge is not in use, it will force the Kaowool to take a set,

and

soon the plug will no longer be necessary. The hole in the inner layer

of

Kaowool will continue the tapering opening of the nozzle, and the 1"

setback

from the chamber will prevent the nozzle from being destroyed

prematurely.

Note about burner

nozzle placement in the forge:

Your burner nozzle should not enter the innermost layer of Kaowool. To

do

so will cause the nozzle to overheat and quickly degrade, or melt all

together.

Using a sharp knife, cut an "X" through both layers of Kaowool in front

of

the burner port, and from the outside, force the burner nozzle into the

forge

while spreading the Kaowool with your fingers to allow the nozzle to

squeeze

in. Stop when your have fully penetrated the outer layer of Kaowool.

Use

some kind of tapered plug, I use a turned hardwood plug, and from the

inside

of the chamber, force it through the X into the burner nozzle while

working

the Kaowool with your fingers to allow the plug to seat home against

and

inside the inner lip of the nozzle. The plug will need to have a

steeper

taper than the 1:12 that is inside the nozzle. By leaving the plug in

place

when the forge is not in use, it will force the Kaowool to take a set,

and

soon the plug will no longer be necessary. The hole in the inner layer

of

Kaowool will continue the tapering opening of the nozzle, and the 1"

setback

from the chamber will prevent the nozzle from being destroyed

prematurely.

The 2-1/2" Diameter Mongo Burner

The Mongo Burner

Series:

Mongo

Burner = 2-1/2" diameter

burner tube (Air starved)

Minimongo Burner

= 1-1/4" diameter

burner tube

Micromongo Burner

= 3/4" diameter burner

tube

Nanomongo Burner

= 1/2" diameter burner

tube

![]() Safety Warnings &

Considerations....a Must

Read:

The Side-arm burner

has now been perfected and can be found at the bottom of this section. You

are building and using this burner entirely at your own risk.

If you

don't wear eye protection, and you loose your eyesight due to the UV

radiation

that these burners can produce, then you are responsible for not

reading

and following the warnings, and must bear all consequences. I will not

accept

any liability for the stupidity of the builder and user of this device

if

he should injure himself with it by ignoring this warning. Please read

the

following e-mail I received. It will give you an idea of

the temperatures

these burners can achieve.

Safety Warnings &

Considerations....a Must

Read:

The Side-arm burner

has now been perfected and can be found at the bottom of this section. You

are building and using this burner entirely at your own risk.

If you

don't wear eye protection, and you loose your eyesight due to the UV

radiation

that these burners can produce, then you are responsible for not

reading

and following the warnings, and must bear all consequences. I will not

accept

any liability for the stupidity of the builder and user of this device

if

he should injure himself with it by ignoring this warning. Please read

the

following e-mail I received. It will give you an idea of

the temperatures

these burners can achieve.

"At this point, my only observation is that the (Micromongo) burner is too hot for the current nozzle design. Don't get me wrong, the burners worked great. I could not get the burners to run quite right without Larry Zoeller's nozzles, but I did not try very long, as I had a job that I had to get done this weekend ( I was already behind because I could not get enough heat out of the Reil Burner ). After going down to the welding store to buy a shaded full face plate (a definite necessity), I got right to work. Things were going great until the burners went erratic. The problem was that the nozzles got yellow+++ hot and sagged over the end of the burner. The nozzles now look like a tuba run over by a semi. I can not wait to get some more nozzles from Mr. Zoeller so I can form up some type of ceramic nozzle and start experimenting with this burner. Great potential. Thx's for all the help. Fred jyblood@nwi.net"

![]() There are a few more

items to address. It is apparent

in our testing that these burners display a very wide range of

behaviors

depending on what jet diameter is employed. Also, we are now using the

long

tapering copper 14T Tweco tips

for our jets,

even on the Reil and EZ-Burners, which I strongly recommend you do also

due

to the greatly increased performance they afford. I suggest you

experiment

with various diameter orifice Tweco tips and settle on one that works

best

for your particular application. See the FAQ for a listing of

nominal

to actual orifice diameters for these tips. They are threaded, 1/4"x 28

thread,

so you can easily switch them for experimentation. I may post a

"recommended

jet diameter" later on for each burner size, but presently I want to

leave

it open ended, even though the Mongo and Minimongo Burners both have

jets

called off in the information below which will provide a good starting

point

for you. Additionally, the tapered nozzle stainless steel flare

operates

at a much higher temperature, a red heat, on the Micromongo Burner than

on

the Reil or EZ Burners. This increased temperature will cause much more

rapid

degradation of the burner flare, even if its made of stainless steel.

In fact I would say that stainless

steel is your best option

for metal nozzles, and even their life may be fairly short, although

proper

mounting of the nozzle 1" back into the Kaowool will greatly extend its

life. I am getting more than three years out of a nozzle

presently. You

may want to consider casting your nozzle flare into the wall of your

rammable

refractory shell, if you have this kind of forge lining, thus

eliminating

the metal nozzle all together. This would be an easy task to perform,

and

may be the very best alternative for these high temperature burners.

Another

possibility is coating the nozzle, either stainless or black iron, with

ITC # 213. Have fun

and be careful!

There are a few more

items to address. It is apparent

in our testing that these burners display a very wide range of

behaviors

depending on what jet diameter is employed. Also, we are now using the

long

tapering copper 14T Tweco tips

for our jets,

even on the Reil and EZ-Burners, which I strongly recommend you do also

due

to the greatly increased performance they afford. I suggest you

experiment

with various diameter orifice Tweco tips and settle on one that works

best

for your particular application. See the FAQ for a listing of

nominal

to actual orifice diameters for these tips. They are threaded, 1/4"x 28

thread,

so you can easily switch them for experimentation. I may post a

"recommended

jet diameter" later on for each burner size, but presently I want to

leave

it open ended, even though the Mongo and Minimongo Burners both have

jets

called off in the information below which will provide a good starting

point

for you. Additionally, the tapered nozzle stainless steel flare

operates

at a much higher temperature, a red heat, on the Micromongo Burner than

on

the Reil or EZ Burners. This increased temperature will cause much more

rapid

degradation of the burner flare, even if its made of stainless steel.

In fact I would say that stainless

steel is your best option

for metal nozzles, and even their life may be fairly short, although

proper

mounting of the nozzle 1" back into the Kaowool will greatly extend its

life. I am getting more than three years out of a nozzle

presently. You

may want to consider casting your nozzle flare into the wall of your

rammable

refractory shell, if you have this kind of forge lining, thus

eliminating

the metal nozzle all together. This would be an easy task to perform,

and

may be the very best alternative for these high temperature burners.

Another

possibility is coating the nozzle, either stainless or black iron, with

ITC # 213. Have fun

and be careful!

![]() A

Note about Economy vs. Efficiency: There

are numerous

comments in my pages about "economy" and "efficiency." They do not mean

the

same thing. As I use these terms, the economy of a

burner refers to

how much its going to cost you to run it. The efficiency

of a burner,

in the way its used in my pages, refers to how much

air it can draw

in due to the strength of the vacuum it creates in the intake

bell

or ports at a given gas pressure. There are only so many BTUs available

in

a pound of propane, and no matter what you do you can not get any more

than

that out. If two different designs of burners are both running with a

totally

neutral burn at 100% combustion, and maintaining two identical forge

chambers

at the same temperature, their economy will be

identical. The Micromongo

Burner can produce higher temperatures than the Reil Burner, but it

uses

more fuel to do this. If you lower the output of the Micromongo so that

the

temperature inside the forge chamber is the same as in an identical

forge

chamber heated with a Reil Burner, the fuel usage, or economy,

should

be the same. If they are not, then one or the other is not running at

optimal

tuning. So don't choose the Micromongo Burner because you think it will

save

you money, it won't. It will give you the ability

to get the same

economy as provided by the Reil Burner, but it will also allow you to

reach

higher temperatures than the Reil Burner can attain, but this will cost

you

more in fuel usage. There is just no free lunch. It

is likely that

overall you will spend more money on fuel with the Micromongo burner

because

you will probably want to use that extra heat range to run a hotter

forge.

You pay for what you get. Note: We were very

surprised by the results

of some recent side by side tests of the T-Rex and Reil burners. They

both

consumed about the same amount of fuel, yet the T-Rex was much hotter.

We

concluded that the mixing and fuel/air ratios in the T-Rex are

superior,

and provide a better burn, thus extracting more of the BTU heat value

from

the fuel than the Reil burner is capable of doing. The T-Rex is both

more

economical, and more efficient. It is more econimical because it can be

run

at a lower gas pressure, using less fuel, and obtain a comparable

temperature

in the chamber.

A

Note about Economy vs. Efficiency: There

are numerous

comments in my pages about "economy" and "efficiency." They do not mean

the

same thing. As I use these terms, the economy of a

burner refers to

how much its going to cost you to run it. The efficiency

of a burner,

in the way its used in my pages, refers to how much

air it can draw

in due to the strength of the vacuum it creates in the intake

bell

or ports at a given gas pressure. There are only so many BTUs available

in

a pound of propane, and no matter what you do you can not get any more

than

that out. If two different designs of burners are both running with a

totally

neutral burn at 100% combustion, and maintaining two identical forge

chambers

at the same temperature, their economy will be

identical. The Micromongo

Burner can produce higher temperatures than the Reil Burner, but it

uses

more fuel to do this. If you lower the output of the Micromongo so that

the

temperature inside the forge chamber is the same as in an identical

forge

chamber heated with a Reil Burner, the fuel usage, or economy,

should

be the same. If they are not, then one or the other is not running at

optimal

tuning. So don't choose the Micromongo Burner because you think it will

save

you money, it won't. It will give you the ability

to get the same

economy as provided by the Reil Burner, but it will also allow you to

reach

higher temperatures than the Reil Burner can attain, but this will cost

you

more in fuel usage. There is just no free lunch. It

is likely that

overall you will spend more money on fuel with the Micromongo burner

because

you will probably want to use that extra heat range to run a hotter

forge.

You pay for what you get. Note: We were very

surprised by the results

of some recent side by side tests of the T-Rex and Reil burners. They

both

consumed about the same amount of fuel, yet the T-Rex was much hotter.

We

concluded that the mixing and fuel/air ratios in the T-Rex are

superior,

and provide a better burn, thus extracting more of the BTU heat value

from

the fuel than the Reil burner is capable of doing. The T-Rex is both

more

economical, and more efficient. It is more econimical because it can be

run

at a lower gas pressure, using less fuel, and obtain a comparable

temperature

in the chamber.

![]() The only exception to

the basic statements above may be when using a Mongo Series

Burner, or

one of the big Rex series burners, to run a melting furnace. If you are

able

to achieve a higher temperature in the furnace with a bigger burner, it

will

achieve the melt more quickly, which cuts the time available for heat

to

escape through the furnace walls and up the stack, thus wasting fewer

BTUs.

However, the higher temperature creates a greater thermal gradient

across

the thickness of the furnace wall, increasing the amount of heat loss

in

a given time, so there is a trade-off to consider. If the Furnace walls

were

made of 100% efficient insulation this relationship would not exist,

and

the burners would perform with equal economy, but perhaps not

convenience.

I point out these various relationships to show you that things are not

as

simple as they may sometimes appear. There are a lot of factors to take

into

account when discussing economy of a burner. For the most part, the

smith

operating the forge, and the quality of the forge, will be the most

important

factors in determining overall economy, not the burner. Think about

running

your burner to do a day's forging, without the benefit of a forge

chamber,

and you will understand my last comment.

The only exception to

the basic statements above may be when using a Mongo Series

Burner, or

one of the big Rex series burners, to run a melting furnace. If you are

able

to achieve a higher temperature in the furnace with a bigger burner, it

will

achieve the melt more quickly, which cuts the time available for heat

to

escape through the furnace walls and up the stack, thus wasting fewer

BTUs.

However, the higher temperature creates a greater thermal gradient

across

the thickness of the furnace wall, increasing the amount of heat loss

in

a given time, so there is a trade-off to consider. If the Furnace walls

were

made of 100% efficient insulation this relationship would not exist,

and

the burners would perform with equal economy, but perhaps not

convenience.

I point out these various relationships to show you that things are not

as

simple as they may sometimes appear. There are a lot of factors to take

into

account when discussing economy of a burner. For the most part, the

smith

operating the forge, and the quality of the forge, will be the most

important

factors in determining overall economy, not the burner. Think about

running

your burner to do a day's forging, without the benefit of a forge

chamber,

and you will understand my last comment.

The Mongo Burner & New Side-arm Burner

Note: For historical purposes, and to keep information available that may be of use to someone, I have not removed the drilled air intake hole Mongo burners from this page, nor the old Side-arm information shown several paragraphs below. The drilled hole ports are too small to provide the necessary intake air volume on the original Mongo burner, resulting in a very rich burn and high CO production...potentially dangerous. The original Side-arm burner design has also proven to be an inferior design if built as shown in this drawing, and I do not recommend it. There is now a far superior option available which turns the Side-arm burner into to a very fine burner by using an asymmetric T-fitting. If you enlarge the "intake" bell opening, as shown in the images linked a couple sentences below, the inlet "R" value will drop to a level to allow these burners to perform extremely well, especially if you use a Tweco 14T jet tip. Larry Zoeller has been experimenting with this concept and has provided some examples of high quality Side-arm burners. Check these out if you want a good example of these very easily and quickly made burners. Paul Pirtle has also been working on these burners and has produced an excellent Side-arm burner, shown with "axial" choke installed, which performs extremely well across the entire pressure range. He has since replaced the cast iron test nozzle with a stainless steel nozzle so that it will not melt in his forge chamber. Please do not use cast iron. The following are a few comments Paul sent me regarding his excellent Side-arm burner. I include it here because the jet orifice information may be of use to you.

"Yesterday I built two air choke assemblies, using a 1-1/4" short nipple with round choke plate, 1/4-20 all-thread, and a brazed T per your design. Tested both, they work perfectly to adjust flame to blue/green transition. Based on how far the choke needed to be closed I think I could run a larger than .035" orifice. I tested the .023 orifice again with choke, it runs fine but fussier than the .035. I am guessing it might be marginal to small for the 3/4" burner tube. A 1-1/4"x 1-1/4" x 3/4" cast iron T-fitting is necessary to provide the needed intake air flow volume for a 3/4" burner." (It may be possible to use a smaller bell on the top end of the fitting where the jet pipe enters, perhaps a 1" x 1-1/4" x 3/4" or even a 3/4" x 1-1/4" x 3/4" fitting.)

![]() The original Mongo

burner

is a huge multi-purpose "Jet Ejector" burner. I was so impressed after

I

built one, even though it had a too short burner tube and no nozzle,

that

I felt it deserved a place on this page. I named it after "Mongo," the

giant

in "Blazing Saddles," because of its huge size.... 2-1/2" diameter

bore!

It is a different design of burner, having seven 1" diameter air holes

in

the barrel of the burner, and an axial 1/2" diameter internal jet tube,

but

it works quite well, except for not being able to get a fully balanced

fuel/air

mixture. It tends to run on the fuel rich side due to the small intake

port

area and resulting insufficient intake air volume. When I first tried

test

firing it I was unable to run it below 20 psi or it would become

erratic

and run extremely rough. I switched out the jet tube for one 1" longer,

to

get the jet just slightly downstream of the air intake openings. This

made

a huge difference. I can now run the pressure down to zero gage

pressure,

doesn't show on my gage at all, but it is probably about 1/10 psi, and

it

purrs away just beautifully at a very reduced output. This low end

operating

range is due to the 28:1 induction ratio of jet ejector burners, as

compared

with the 20:1 ratio for the linear inducer burner like the "Reil or EZ

Burners."

This burner has tremendous adjustability in its output, making it

useful

for kilns, but the possible CO dangers need to be considered and

precautions

taken. For forge use, I strongly recommend going to an asymetric

Side-arm

design as shown at the top of this

section, and use

of a flared nozzle.

The original Mongo

burner

is a huge multi-purpose "Jet Ejector" burner. I was so impressed after

I

built one, even though it had a too short burner tube and no nozzle,

that

I felt it deserved a place on this page. I named it after "Mongo," the

giant

in "Blazing Saddles," because of its huge size.... 2-1/2" diameter

bore!

It is a different design of burner, having seven 1" diameter air holes

in

the barrel of the burner, and an axial 1/2" diameter internal jet tube,

but

it works quite well, except for not being able to get a fully balanced

fuel/air

mixture. It tends to run on the fuel rich side due to the small intake

port

area and resulting insufficient intake air volume. When I first tried

test

firing it I was unable to run it below 20 psi or it would become

erratic

and run extremely rough. I switched out the jet tube for one 1" longer,

to

get the jet just slightly downstream of the air intake openings. This

made

a huge difference. I can now run the pressure down to zero gage

pressure,

doesn't show on my gage at all, but it is probably about 1/10 psi, and

it

purrs away just beautifully at a very reduced output. This low end

operating

range is due to the 28:1 induction ratio of jet ejector burners, as

compared

with the 20:1 ratio for the linear inducer burner like the "Reil or EZ

Burners."

This burner has tremendous adjustability in its output, making it

useful

for kilns, but the possible CO dangers need to be considered and

precautions

taken. For forge use, I strongly recommend going to an asymetric

Side-arm

design as shown at the top of this

section, and use

of a flared nozzle.

![]() The original

Mongo burner

design discussed in the paragraph above was sent to me by Richard Mize,

in

Kentucky, and I have to thank him very much for sharing it with us. He

included

some additional information and suggestions in his drawings which I too

included

in the packet of drawings. I did not build the refractory venturi

throat,

nor the bracket he suggests, at least not yet. I have simply run scans

of

Richard's hand drawings and posted them below

for

download. It is a zipped file containing 6 images, including an

assembly

drawing, text comment sheets, refractory venturi throat, mounting

bracket,

mounting suggestions, and a list of materials needed. I have reduced

them

in size to allow downloading to be faster, but all together they are

still

264K in size. These are hand drawings with hand written notes. They

were

plenty good enough for me to produce a dandy burner, and I am sure they

will

work just as well for you. An alternative that I strongly recommend due

to

its small file size is the "pdf" Adobe Acrobat file I have

available

also. This is a single fine quality drawing, with fewer notes and

comments,

and it is a much smaller file. It should be plenty detailed to allow

you

to build the burner without problem. Click on the gif "preview file" to

see

a reduced size image of the "pdf" construction file. The preview image

may

be all you will need to build this burner, but the text is

pretty small

for older eyes like mine. I do want to say that I strongly suggest the

Side-arm

burner discussed above, which is easier to build and produces a fully

balanced

fuel/air ratio, and no CO danger if adjusted correctly.

The original

Mongo burner

design discussed in the paragraph above was sent to me by Richard Mize,

in

Kentucky, and I have to thank him very much for sharing it with us. He

included

some additional information and suggestions in his drawings which I too

included

in the packet of drawings. I did not build the refractory venturi

throat,

nor the bracket he suggests, at least not yet. I have simply run scans

of

Richard's hand drawings and posted them below

for

download. It is a zipped file containing 6 images, including an

assembly

drawing, text comment sheets, refractory venturi throat, mounting

bracket,

mounting suggestions, and a list of materials needed. I have reduced

them

in size to allow downloading to be faster, but all together they are

still

264K in size. These are hand drawings with hand written notes. They

were

plenty good enough for me to produce a dandy burner, and I am sure they

will

work just as well for you. An alternative that I strongly recommend due

to

its small file size is the "pdf" Adobe Acrobat file I have

available

also. This is a single fine quality drawing, with fewer notes and

comments,

and it is a much smaller file. It should be plenty detailed to allow

you

to build the burner without problem. Click on the gif "preview file" to

see

a reduced size image of the "pdf" construction file. The preview image

may

be all you will need to build this burner, but the text is

pretty small

for older eyes like mine. I do want to say that I strongly suggest the

Side-arm

burner discussed above, which is easier to build and produces a fully

balanced

fuel/air ratio, and no CO danger if adjusted correctly.

![]() Alternate Side-arm

Design:

(Note: this is older information, but is preserved for its historical

value.

Please see the latest Side-arm information at the top

of this section.) You can build this burner more easily if

you substitute

a large "T" fitting, see link, in place of the pipe coupling.

The burner

tube screws into one arm of the "T", and the reducer and jet tube into

the

other arm. The air intake is provided by the opening in the base of the

"T"

fitting. You will not need to drill the big air intake holes this way.

Also,

it can be easily choked using a butterfly choke design, or an axial

choke

design, which is placed in the "foot" of the "T". You will have to

experiment

to determine the proper length of axial jet tube in order to place the

jet

in the right location in relation to the incoming air. I have not tried

these

modifications to the burner design. (Thanks goes to "Frosty"

in Alaska

for this suggestion, and the induction ratio information above.)

Robert Grauman

has built one

he has named the "Side-arm Design,"

in the Minimongo

diameter, and this is what he has to say. (Note: I strongly recommend

using

a 1/8" jet tube, instead of the 1/4" tube shown in the

drawing.) "I used to have a choke plate in

the air tube, but I

found I was getting a neutral burn with the choke wide open, so I

removed

the choke, and am now running with the inlet wide open. This has

simplified

the burner considerably. I am using a #55 (0.052") jet at about 22 psi.

The

flame burns near neutral (I think), but it requires a flame holder on

the

end of the burner tube when the burner is not in the burner port of my

crucible furnace. It burns quietly. If provoked, the

flame will burn

back in the burner tube, but I believe that the burner tube is too

long.

I will start experimenting in that area tomorrow. The burner seems to

work

best with the jet cantered on the air tube, but it is non-critical."

Alternate Side-arm

Design:

(Note: this is older information, but is preserved for its historical

value.

Please see the latest Side-arm information at the top

of this section.) You can build this burner more easily if

you substitute

a large "T" fitting, see link, in place of the pipe coupling.

The burner

tube screws into one arm of the "T", and the reducer and jet tube into

the

other arm. The air intake is provided by the opening in the base of the

"T"

fitting. You will not need to drill the big air intake holes this way.

Also,

it can be easily choked using a butterfly choke design, or an axial

choke

design, which is placed in the "foot" of the "T". You will have to

experiment

to determine the proper length of axial jet tube in order to place the

jet

in the right location in relation to the incoming air. I have not tried

these

modifications to the burner design. (Thanks goes to "Frosty"

in Alaska

for this suggestion, and the induction ratio information above.)

Robert Grauman

has built one

he has named the "Side-arm Design,"

in the Minimongo

diameter, and this is what he has to say. (Note: I strongly recommend

using

a 1/8" jet tube, instead of the 1/4" tube shown in the

drawing.) "I used to have a choke plate in

the air tube, but I

found I was getting a neutral burn with the choke wide open, so I

removed

the choke, and am now running with the inlet wide open. This has

simplified

the burner considerably. I am using a #55 (0.052") jet at about 22 psi.

The

flame burns near neutral (I think), but it requires a flame holder on

the

end of the burner tube when the burner is not in the burner port of my

crucible furnace. It burns quietly. If provoked, the

flame will burn

back in the burner tube, but I believe that the burner tube is too

long.

I will start experimenting in that area tomorrow. The burner seems to

work

best with the jet cantered on the air tube, but it is non-critical."

![]() Please note that

Robert

uses the burner in a cast iron and aluminum melting furnace, not a

forge.

You will want to operate at much lower pressures for forge work. Note:

From tests done by Michael, it appears the "Sidearm" design is not a

good

choice for the smaller Micromongo and Nanomongo burners. He was unable

to

achieve a stable flame over a range of gas pressures in his Sidearm

Micromongo

test burner.

Please note that

Robert

uses the burner in a cast iron and aluminum melting furnace, not a

forge.

You will want to operate at much lower pressures for forge work. Note:

From tests done by Michael, it appears the "Sidearm" design is not a

good

choice for the smaller Micromongo and Nanomongo burners. He was unable

to

achieve a stable flame over a range of gas pressures in his Sidearm

Micromongo

test burner.

![]() Note:

There is one important

error in the Adobe Acrobat "pdf" file below. The jet opening should

read

"#52 = 0.0625" diameter", not #58. This is a very

important

difference.

Note:

There is one important

error in the Adobe Acrobat "pdf" file below. The jet opening should

read

"#52 = 0.0625" diameter", not #58. This is a very

important

difference.

Preview the Following "pdf" file as a Reduced Size "gif" Image

Download a Single Complete Design File in "pdf" Format (Recommended - 16K)

Download all Six Construction Drawings in Zipped "gif" Format (264K)

(Before considering the construction of any of the Mongo series of burners, please read the informationa about the Side-arm burners at the top of this section.)

![]() If you don't have

"Adobe

Acrobat Reader" on your computer you may

download

it

here, its free.

If you don't have

"Adobe

Acrobat Reader" on your computer you may

download

it

here, its free.

![]() "Minimongo

Burner":

I received a communication

from Rupert Wenig

regarding a

half scale version of the

Mongo Burner that he is

using to fire his cast iron melting furnace. His experimentation work

is

continuing, but here are his latest design modification details. He is

getting

good results with it using these parameters. See the cast iron test

melt

results below the following specs Rupert provided. For forge use, I

strongly

recommend going to an asymetric Side-arm design as shown at the

top of this section, and use

of a flared nozzle.

"Minimongo

Burner":

I received a communication

from Rupert Wenig

regarding a

half scale version of the

Mongo Burner that he is

using to fire his cast iron melting furnace. His experimentation work

is

continuing, but here are his latest design modification details. He is

getting

good results with it using these parameters. See the cast iron test

melt

results below the following specs Rupert provided. For forge use, I

strongly

recommend going to an asymetric Side-arm design as shown at the

top of this section, and use

of a flared nozzle.

-Burner tube: black iron pipe,

1-1/4" diameter by 12" long

-Jet: #56 drill = 0.0465"diameter (You may need to experiment further

to

determine the optimum jet opening)

-Air induction holes: 13/16" diameter

-Additional changes in Rupert's own words: "I

also changed the

pipe bushing to a standard easier to get one. As pipe bushings are not

normally

solid I made a plug to fit the inside of the bushing to give the fuel

pipe

more surface area to hold it straight. I then drilled a clearance hole

through

the plug and bushing and installed a set screw to clamp the fuel pipe

in

place. This allowed adjusting the position of the fuel jet. Another

change

I made for convenience was to thread the inside of the fuel pipe so

that

I could use the jets I had on hand."

"PS. There is no

question that this burner is quieter than other burners I have

tried."

![]() Rupert's

Cast Iron

Melt Results Using the Minimongo Burner Without Flared

Nozzle:

Rupert's

Cast Iron

Melt Results Using the Minimongo Burner Without Flared

Nozzle:

I did a cast iron melt with the Minimongo today. I

ran the furnace

for 1:12 hrs, melting 15# of cast iron while running the burner at 20

psi

after a 2 min. warm up from a cold start-up. That equates to about 0.21

lb/min.

From my logs the Monster burner melted 17 lb. in 1:13 hrs. This equates

to

0.23 lb./min.

Unfortunately, the casting didn't turn out because I got impatient. I should have superheated the melt for another 2 or 3 min as the casting I poured was a very thin section (1/4"). I would say that this compares favorably (with the Monster burner) as the Minimongo has a #56 jet in it while the Monster burner had a #54 jet.

![]() Based on the

latest

information I am receiving, you will need to make a 1:12 tapered nozzle

flare,

for the Minimongo burner, and probably for the Mongo Burner as well,

once

it has been fully tuned.

Based on the

latest

information I am receiving, you will need to make a 1:12 tapered nozzle

flare,

for the Minimongo burner, and probably for the Mongo Burner as well,

once

it has been fully tuned.

![]() Thanks to the work

of

Robert Grauman

in "Sunny Alberta,"

we now have a very fine jpg drawing of the "Minimongo Burner" that

Rupert

has provided information for. You may click the link below to view the

design

drawing. This drawing incorporates all of Rupert's modifications to the

full

scale version, including some details he did not mention above. Thanks

Robert.

Thanks to the work

of

Robert Grauman

in "Sunny Alberta,"

we now have a very fine jpg drawing of the "Minimongo Burner" that

Rupert

has provided information for. You may click the link below to view the

design

drawing. This drawing incorporates all of Rupert's modifications to the

full

scale version, including some details he did not mention above. Thanks

Robert.

Mongo

Burner Half Scale Design

Drawing

Note: I strongly recommend using

a 1/8" jet tube, instead

of the 1/4" tube shown in the drawing.

![]() Choke

Settings

Image: The below linked image is a

composite image of six

images Rupert sent me of his Minimongo Burner, photographed at three

different

choke settings, rich, neutral, and lean. All the images were shot at a

gas

pressure setting of 10 psi. The images on the right were taken without

flash

to show the flame characteristics more clearly. This is a long needed

set

of images that are very helpful when attempting to tune any kind of

burner

for a neutral burn, not just the Mongo or Minimongo Burners. Note:

The coupling that Rupert is using for his flared nozzle has been

machined

out to have a 1:12 internal rate of flare...it is not just a coupling.

Choke

Settings

Image: The below linked image is a

composite image of six

images Rupert sent me of his Minimongo Burner, photographed at three

different

choke settings, rich, neutral, and lean. All the images were shot at a

gas

pressure setting of 10 psi. The images on the right were taken without

flash

to show the flame characteristics more clearly. This is a long needed

set

of images that are very helpful when attempting to tune any kind of

burner

for a neutral burn, not just the Mongo or Minimongo Burners. Note:

The coupling that Rupert is using for his flared nozzle has been

machined

out to have a 1:12 internal rate of flare...it is not just a coupling.

Minimongo Showing Flame Under Different Choke Settings at 10 psi Gas Pressure

(Be sure you also look at the full output image)

![]() Micromongo and Nanomongo

Burner

Designs: We

now have good Micromongo and Nanomongo

Burners in operation, and the development work is complete.

Michael has

performed virtually all

the development work for this burner, while communicating and

discussing